In the realm of strategic industries impacting national economies, politics, and defense security, the semiconductor sector stands as a pivotal player. Within this domain, cutting-edge equipment, epitomized by photolithography machines, represents the epitome of modern, highly integrated technology. Spanning disciplines like optics, materials science, and computer science, the design and manufacturing processes showcase the pinnacle of scientific and technological prowess. Notably, these machines impose exacting demands on precision components, with advanced ceramics emerging as a formidable third-generation material, playing a crucial role.

In the realm of high-end photolithography machines, the demand for highly efficient, precise, and stable motion control and drive technologies sets exceedingly high standards for component precision and material performance.

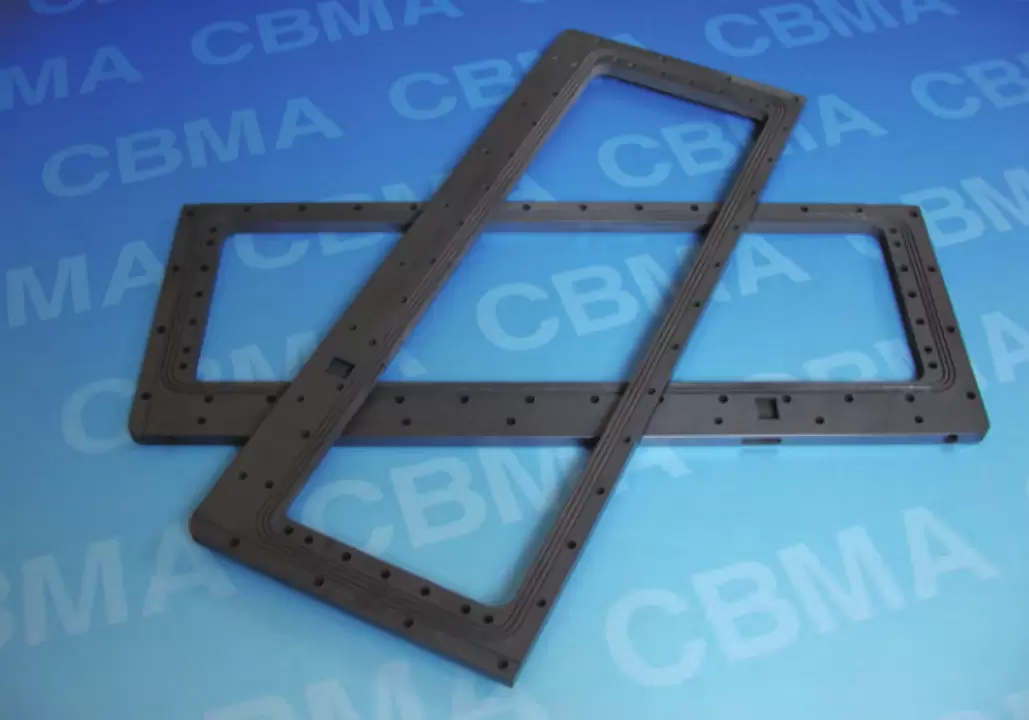

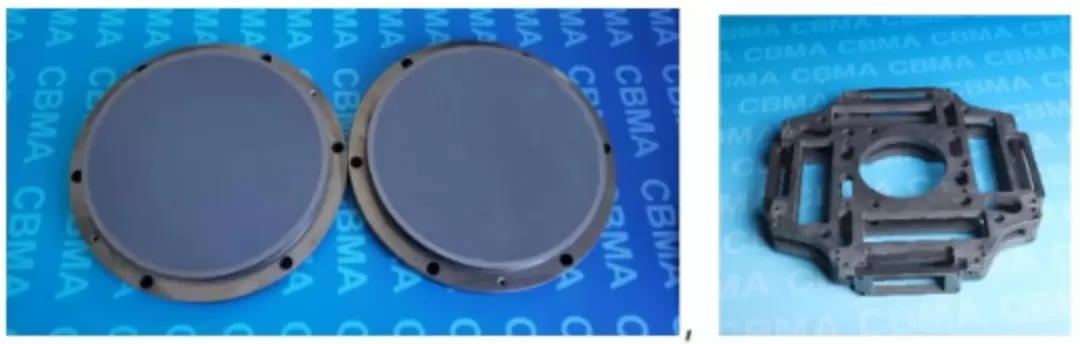

Silicon carbide ceramics, with an exceptionally high elastic modulus, thermal conductivity, and a low coefficient of thermal expansion, mitigate issues like bending stress deformation and thermal strain. Moreover, their superb polishability allows for mechanical processing to achieve optimal mirrors. Thus, leveraging silicon carbide ceramics as the material for precision structural components in semiconductor critical equipment, such as photolithography machines, proves to be highly advantageous. Components requiring silicon carbide ceramics in semiconductor manufacturing equipment encompass worktables, guide rails, reflective mirrors, arms, blocks, magnetic steel frameworks, suction cups, water-cooled plates, and air-floating boards.

These components exhibit distinctive structural features:

Large dimensions and thickness

Hollow closed-hole structures

Thin-walled, thin-plate structures

High degree of lightweight construction

Elevated positional accuracy

Excellent optical performance

These characteristics present significant manufacturing challenges for silicon carbide ceramic components, restraining their widespread application in the high-end equipment manufacturing sector. Currently, only a handful of developed countries, including Japan and the United States, represented by companies like Kyocera and CoorsTek, have successfully integrated silicon carbide ceramic materials into critical semiconductor equipment.

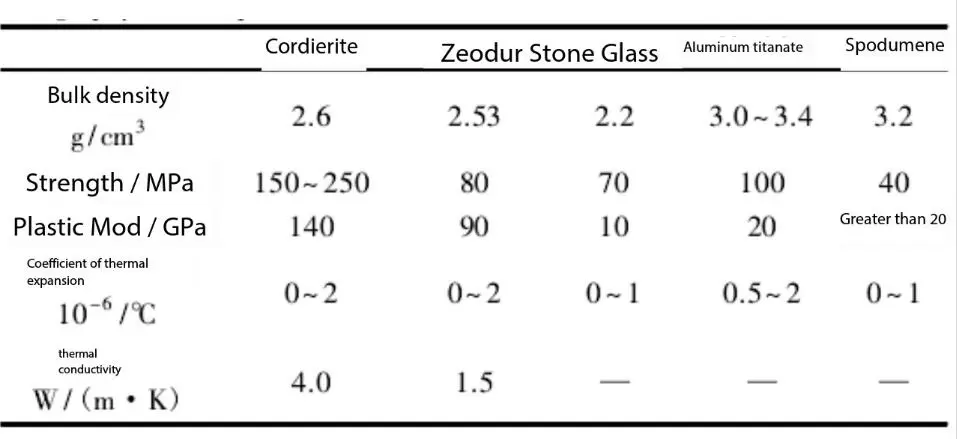

The material system design for the platforms of photolithography machines is pivotal for achieving high precision and speed. Overcoming deformation during high-speed scanning requires materials with a high stiffness-to-weight ratio — low thermal expansion materials fitting this criterion.

Traditionally, German company Schott's microcrystalline glass (Zerodur), quartz glass, and ULE glass were employed in early photolithography equipment. Zerodur, in particular, boasts a near-zero coefficient of thermal expansion across a broad temperature range, offering some strength and hardness. However, its low elastic modulus necessitates increased thickness for maintaining the required rigidity, hindering lightweight design and falling short of meeting the demands of high-speed, high-precision photolithography machine platforms. Moreover, Zerodur is prone to wear during EUV ion beam etching, leading to a decline in accuracy.

With the growing demand for advanced photolithography machines, companies like ASML, NIKON, and CANON began researching new material systems for platform structural materials. Jadeite, commonly used in high-temperature environments, gained attention due to its low thermal expansion, low density, and high elastic modulus.

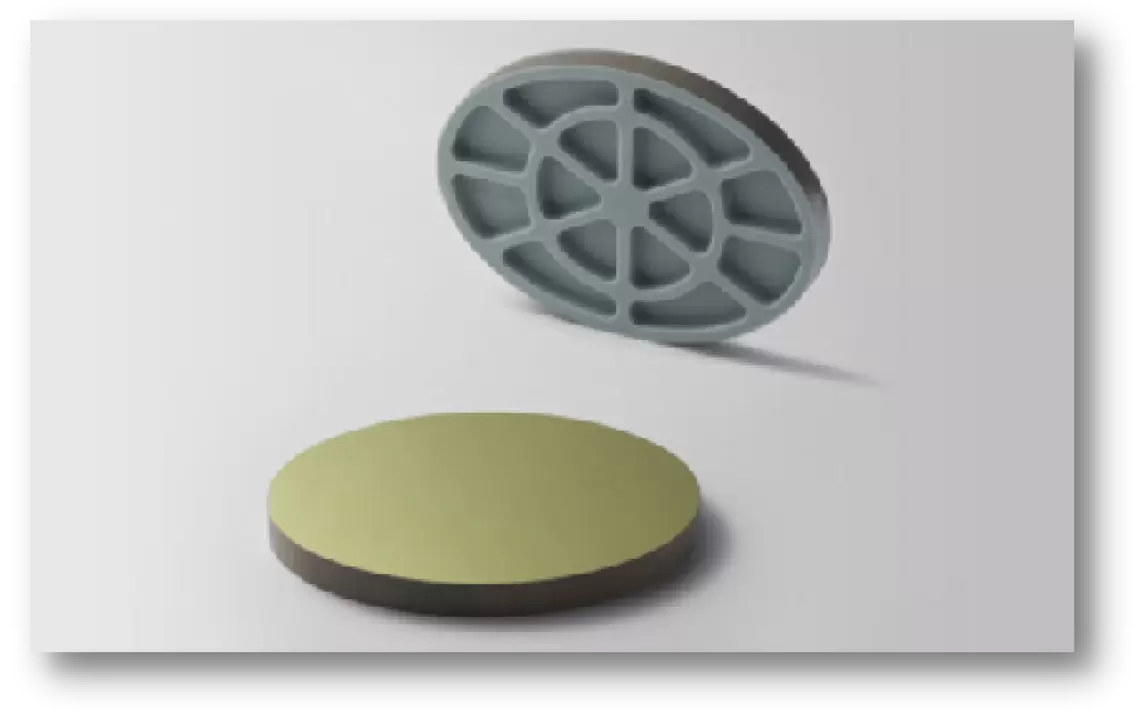

Jadeite boasts a thermal expansion coefficient comparable to Zerodur, ensuring thermal stability. Additionally, its thermal conductivity is nearly three times that of Zerodur, allowing for more effective heat dissipation during use, meeting thermal stability requirements. With a high elastic modulus, Jadeite effectively resists deformation during high-speed platform scanning, enhancing stability. Opting for Jadeite as the platform substrate material, based on stiffness conditions, significantly reduces the required mass compared to microcrystalline glass and quartz glass, fulfilling the need for lightweight design. Hence, researchers worldwide are recognizing Jadeite as a promising material for the next generation of semiconductor photolithography machine platforms.

ASML has been at the forefront of applying Jadeite ceramic in the research and development of photolithography machine platform materials, continually refining and updating the structure. Several publicly disclosed patents by ASML highlight the application and research of Jadeite ceramic in high-end photolithography machine platform materials. Today, ASML has successfully matured and propagated the use of Jadeite ceramic in components of photolithography machine platforms.

Beyond platform applications, Jadeite ceramic finds utility in other components such as reflective mirrors and mask plates. Leading international integrated circuit equipment manufacturers, including ASML, NIKON, CANON, and ZYGO in the United States, extensively utilize materials like microcrystalline glass and Jadeite in the preparation of photolithography machine reflective mirrors. In 2015, Zygo publicly disclosed a photolithography mask material primarily composed of Jadeite ceramic, featuring a finely polished Jadeite substrate layer, a reflective layer, an intermediate cover layer, and an absorbent damping layer. The Jadeite ceramic substrate's elastic modulus ranges from 120 to 150 GPa, with a volume density of 2.5 to 2.7 g/cm³, a thermal expansion coefficient of 0.2×10⁻⁶/℃, and a thermal conductivity of 3 to 5 W/(m·K), all within a thickness of less than 0.635 cm.

Being one of the most intricate devices ever crafted by humanity, photolithography machines demand the control of wave aberrations in projection lenses down to the sub-nanometer level, approaching "zero aberration." Simultaneously, the worktable and mask table require exceptionally high acceleration and nano-level synchronization accuracy. Moreover, during high-speed exposure, the silicon wafer's surface must consistently remain within a focus depth range of approximately 100 nm of the projection lens. As semiconductor processes edge closer to the 5nm physical limit, the design complexity and processing precision of photolithography machines experience an exponential surge, posing significant challenges in nano-level positioning, sub-nanometer processing precision, and precise environmental control.

Throughout the manufacturing and application of photolithography machines, various aspects, including nanoscale fine-tuning of projection lenses, precise positioning during exposure, and active vibration reduction, may employ piezoelectric driving technology to ensure imaging quality, resolution, and stability. Notably, piezoelectric ceramic materials, with characteristics such as non-magnetic interference, high positioning resolution, and minimal heat generation, find extensive use in the positioning actuators of aberration compensation mirrors in photolithography machine projection lenses. Commercially available multilayer piezoelectric actuators often employ zirconium titanate lead (PZT) as the base piezoelectric material, either in a solid solution or with doping modifications.

The development of photolithography machines is a profoundly intricate system engineering endeavor, encompassing top-tier technologies from diverse fields such as optics, precision machining, control systems, and cutting-edge materials. Many of these technologies are rapidly approaching engineering limits. To achieve high process accuracy, advanced ceramics, as critical component materials, find extensive applications in semiconductor equipment, particularly those represented by photolithography machines.

As a vital component of semiconductor production equipment, the research and production of advanced ceramic materials directly influence the development of the semiconductor equipment manufacturing industry and the entire semiconductor industry chain. Despite China's relatively late entry into semiconductor equipment, several critical technological challenges in the preparation of ceramic components need to be overcome. Therefore, considering both economic security and industry cost perspectives, the indigenous development of key materials for semiconductor production equipment, such as advanced ceramic components, is imperative to overcome the bottlenecks faced by the semiconductor industry in China.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder