Grinding is a critical step in mineral processing, where ore particles are reduced in size and target minerals are liberated through collision, impact, and abrasion between the media and ore. Currently, ball mills are the primary equipment for fine grinding, offering advantages such as high crushing ratio, excellent grinding performance, and strong adaptability. However, ball mills primarily rely on the impact and collision of grinding media to break down minerals, resulting in low grinding efficiency, as only a portion of the energy is utilized for ore fragmentation and grinding. Consequently, ball mills generally suffer from low grinding efficiency, high energy consumption, severe liner wear, and poor performance in ultrafine grinding. Stirred mills, on the other hand, operate through abrasive friction, offering advantages such as low energy consumption, high grinding efficiency, and a narrow particle size distribution, making them highly efficient ultrafine grinding equipment. Due to the high energy and ball consumption in fine grinding operations, an increasing number of concentrators are adopting stirred mills for this stage.

Currently, the grinding media used in stirred mills include steel balls, cast iron balls, and ceramic balls, with steel balls being the most widely applied. However, in actual grinding production, steel balls exhibit high roundness loss, high density, poor grinding performance, and short liner lifespan. Moreover, they tend to cause overgrinding of target minerals in ultrafine grinding, greatly limiting their application in stirred mills. Nano-ceramic balls, made from wear-resistant materials such as alumina, zirconia, or silicon boride, offer advantages such as low density, lightweight, excellent heat resistance, superior wear resistance, and strong acid and alkali resistance. Therefore, adopting nano-ceramic balls represents a promising technical solution, attracting significant attention from researchers. For example, Sanxin New Materials Co., Ltd. developed a wear-resistant sub-nano ceramic ball through high-temperature calcination with the addition of oxides and rare earth materials, significantly improving material uniformity and wear resistance. Wear resistance tests showed that these sub-nano ceramic balls far outperform steel balls, reducing ball consumption by over 84% at the same grinding efficiency. Comparative studies on the grinding efficiency of nano-ceramic balls and steel balls revealed that while the particle size distribution of ground products was similar, nano-ceramic balls exhibited higher energy utilization, less overgrinding, and better ultrafine grinding performance.

The concentrator of Diqing Nonferrous Pulang Copper Mine uses a CSM-850 vertical ball mill for coarse concentrate regrinding, which is beneficial for improving the liberation of copper-bearing minerals, reducing overgrinding, and significantly enhancing the recovery rate and grade of copper in subsequent flotation. However, during the initial production phase, the vertical mill employed steel balls as grinding media, and the grinding fineness consistently failed to meet the design target (−0.049 mm > 86%). Therefore, finding a new grinding medium to replace steel balls is crucial for improving grinding efficiency and reducing costs.

This study addresses this issue by comparing the grinding performance of nano-ceramic balls and steel balls in the regrinding of coarse concentrate at Pulang Copper Mine, aiming to explore technical approaches for enhancing grinding efficiency and lowering costs.

The concentrator of Diqing Nonferrous Pulang Copper Mine adopts the SABC + bulk flotation process. The SABC (SAG-Ball-Crush) process consists of a semi-autogenous grinding (SAG) mill, ball mill, and pebble crusher for ore crushing and grinding. The bulk flotation process follows a one-stage roughing – regrinding of rough concentrate – three-stage scavenging – two-stage cleaning circuit.

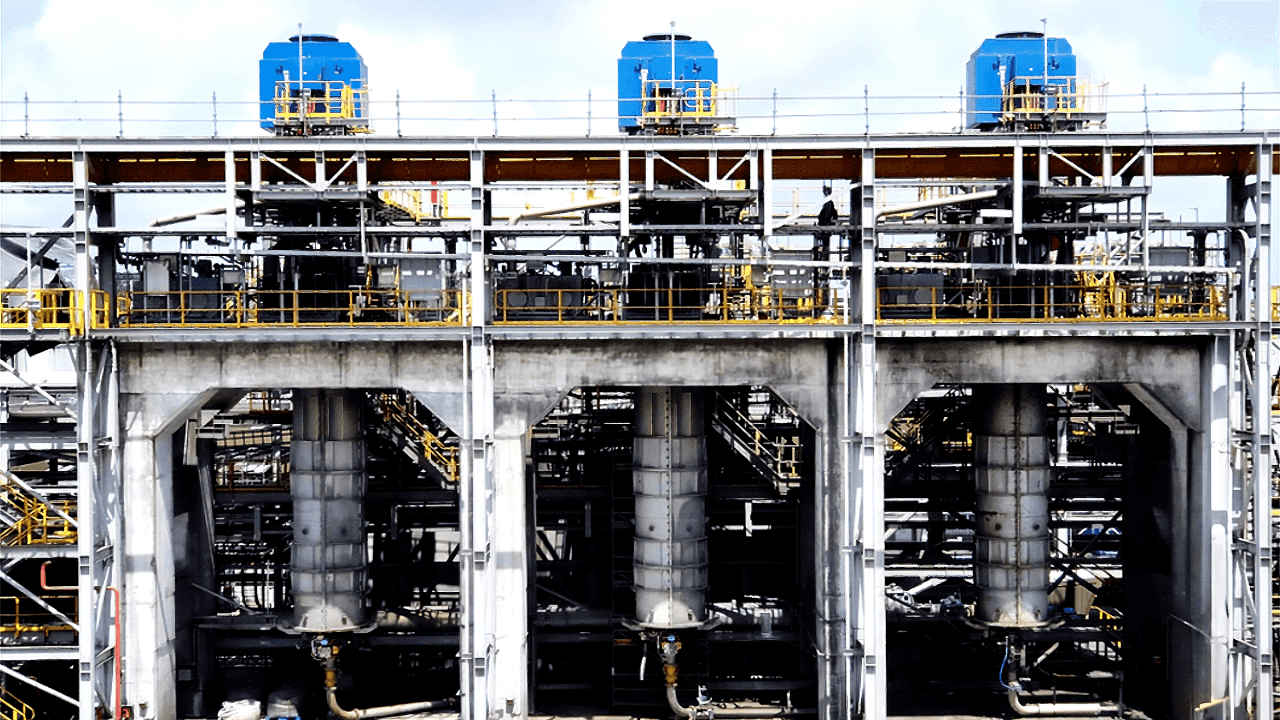

The regrinding of rough concentrate aims to further liberate target minerals, thereby improving the grade of the bulk concentrate and ensuring optimal flotation performance. The CSM-850 vertical mill is used for the regrinding of flotation rough concentrate.

The CSM-850 vertical mill has an effective volume of 45.4 m³. In the initial production phase, the mill used Φ25 mm steel balls as grinding media. To ensure grinding efficiency, the initial ball loading was 75 t, with a filling rate of 34%. The daily ball replenishment was 1 t/d, resulting in a specific ball consumption of 42.56 g/t. The operating current of the mill was approximately 42 A, and the spiral liner lifespan was about 6 months, with 4–6 liners replaced per cycle.

When using steel balls as grinding media, the regrinding fineness in the second stage of the vertical mill was approximately 84% passing 300 mesh (−0.049 mm), slightly below the required technical parameter. Additionally, the following drawbacks were observed in actual production:

Steel balls are prone to deformation and loss of roundness, leading to accumulation and compaction at the bottom of the mill, reducing the effective grinding volume.

"Dented" surfaces develop on steel balls (as shown in Figure 1), causing inefficient grinding and reducing overall grinding efficiency.

To improve grinding efficiency and reduce costs, the Pulang Copper Mine concentrator replaced steel balls with nano-ceramic balls as grinding media in the regrinding of rough concentrate. The initial filling rate of ceramic balls was increased from 30% to 34%, with a total loading of 39 t. The initial ball size distribution was set at m(Φ10 mm) : m(Φ15 mm) : m(Φ20 mm) = 3:4:3, corresponding to:

Φ10 mm ceramic balls: 12 t

Φ15 mm ceramic balls: 15 t

Φ20 mm ceramic balls: 12 t

Pulp density and grinding fineness are key indicators of grinding efficiency. Therefore, a comparative analysis was conducted on the cyclone overflow density and fineness when using ceramic balls versus steel balls. The results are summarized in Table 1.

The comparison revealed that:

Overflow pulp density was similar for both media, falling within the required range (17%–24%).

However, when steel balls were used, pulp density fluctuated significantly (17.27%–23.62%).

In contrast, with ceramic balls, pulp density stabilized at around 20%, facilitating better control of downstream cleaning operations.

Moreover, replacing steel balls with ceramic balls significantly improved grinding fineness, demonstrating a clear enhancement in grinding efficiency.

Particle size distribution and grinding selectivity are critical parameters for evaluating grinding performance. A comparative particle size analysis was conducted on ground products using both steel balls and ceramic balls as grinding media, with the results presented in Table 2. It should be noted that the previously mentioned "-0.049 mm content" in the study on pulp density and grinding fineness refers to the particle size distribution of cyclone overflow products, whereas the grinding fineness discussed in this section pertains to the particle size of the ground product discharged directly from the outlet of the vertical ball mill.

The results in Table 2 demonstrate that when ceramic balls were used as grinding media, the content of coarse particles (+300 mesh) in the ground product significantly decreased. Specifically, the content and generation rate of fine particles (-300 mesh) markedly increased, with the -300 mesh fraction content rising by nearly 8 percentage points. Notably, the content of the -400 mesh fraction increased by approximately 10 percentage points, indicating a substantial improvement. These findings confirm that using ceramic balls as grinding media can effectively enhance grinding efficiency.

In actual production, based on feed characteristics and product particle size distribution, we optimized the diameter and replenishment rate of grinding media. The final determined ceramic ball replenishment rate was 150 kg/d, with a replenishment diameter of Φ20 mm. Details of the media replenishment are shown in Table 3.

As evident from Table 3, after replacing steel balls with ceramic balls as grinding media, the daily replenishment quantity of grinding media decreased significantly. This indicates that ceramic balls can substantially reduce grinding media consumption. For instance:

The specific consumption of ceramic balls was 7.91 g/t, compared to 42.79 g/t for steel balls.

After switching to ceramic balls, the specific media consumption decreased by 34.88 g/t, representing an 82.32% reduction.

Furthermore, visual inspection of the grinding media inside the vertical mill cylinder revealed that ceramic balls effectively maintained their spherical shape, with virtually no out-of-roundness observed (Figure 2). This demonstrates that ceramic balls can significantly reduce media wear and consumption.

While maintaining grinding efficiency, the vertical mill's operating current significantly decreased to 31 A when using ceramic balls as grinding media, compared to the previous 42 A with steel balls. Detailed power consumption data is presented in Table 4.

Key findings from Table 4 show:

The mill's operating current dropped from 42 A (steel balls) to 31 A (ceramic balls)

Specific power consumption decreased from 0.69 kW·h/t to 0.52 kW·h/t

This represents a 25.71% reduction in energy usage

These results demonstrate that adopting ceramic balls as grinding media can substantially reduce grinding energy consumption while maintaining processing efficiency.

The wear and consumption of mill liners represent a significant portion of grinding costs. We conducted a comparative analysis of liner replacement frequency between ceramic ball and steel ball grinding media, with results presented in Table 5.

Key findings demonstrate:

Extended service life:

Cost reduction:

Reduced replacement quantity:

This data confirms that ceramic balls significantly reduce liner wear and associated maintenance costs while maintaining grinding efficiency.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder