Maximize Industrial Equipment Lifespan with Three-in-One Wear-Resistant Ceramic Liners

In industries where equipment faces relentless wear and tear, investing in advanced wear-resistant solutions is no longer optional—it's essential. Among the most effective innovations is the three-in-one wear-resistant ceramic liner, a cutting-edge composite material designed for superior durability, impact resistance, and corrosion protection. This advanced liner integrates alumina ceramics, impact-buffering rubber, and a steel plate base, making it an ideal choice for heavy-duty industrial environments.

Let’s explore the structure, benefits, and application of this high-performance solution engineered for some of the harshest industrial conditions.

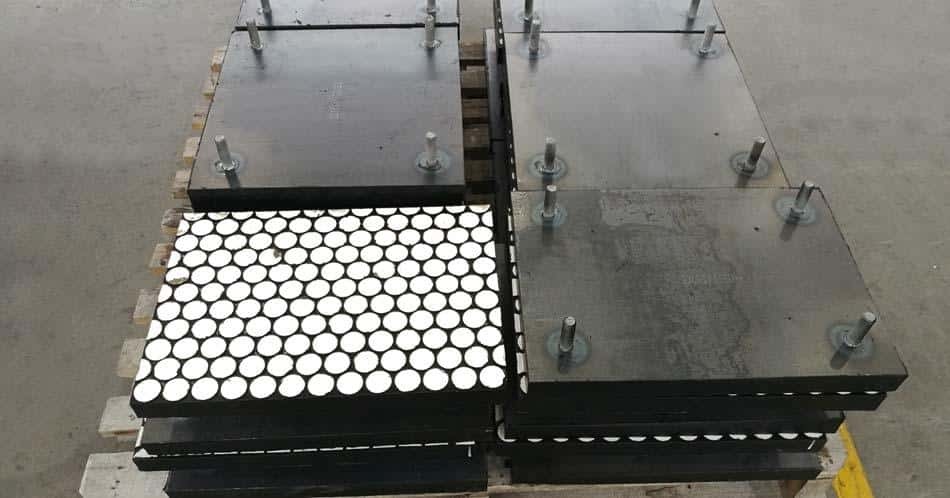

A three-in-one ceramic liner is a high-performance protective solution crafted by combining alumina ceramic (Al₂O₃, ≥92%), a specially formulated acid and alkali-resistant rubber buffer, and a reinforced steel backing plate. The composite is manufactured using a specialized vulcanization and anchoring process, resulting in a tightly bonded, high-strength wear layer capable of withstanding extreme mechanical stress and corrosive environments.

This triple-layer system performs the functions of wear resistance, impact absorption, and corrosion protection in a single product—delivering unmatched protection for industrial equipment.

At the core of the liner lies high-purity alumina ceramics, known for their exceptional hardness—rated above HRA85. This ceramic offers wear resistance up to 270 times greater than traditional manganese steel, significantly extending the operational life of critical equipment.

The inclusion of a toughened ceramic design and energy-absorbing rubber layer effectively disperses shock from bulk materials. This ensures the ceramic tiles remain intact even in applications with high material impact, such as chutes and hoppers.

The rubber layer is engineered with a corrosion-resistant formulation, providing stability in weak acid and alkali environments. The liner operates reliably in temperatures ranging from 0℃ to 250℃, making it suitable for demanding thermal conditions.

Using a vulcanization bonding technique, the ceramic is fused to the rubber layer, and the entire assembly is mechanically fixed to the steel plate using penetrating bolts. This configuration prevents delamination or dislodging under mechanical stress, ensuring long-term durability.

The pre-assembled modular design facilitates quick on-site installation and easy replacement, helping industries reduce downtime and maintenance expenses.

Ceramic Layer: High-density alumina ceramic (≥92% content, ≥3.6 g/cm³ density)

Buffer Layer: Specialized acid and alkali-resistant rubber for shock absorption

Backing Plate: Steel matrix with bolt-through fixing for structural support

Three-in-one ceramic liners are widely applied in high-wear environments across various industries. These liners play a crucial role in minimizing equipment degradation, reducing unscheduled shutdowns, and enhancing operational efficiency.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder