In the wave of global energy transition, a German research team has made a groundbreaking achievement, bringing revolutionary breakthroughs to the field of sustainable energy technology with its consistent rigorous research attitude and outstanding technological innovation capabilities. On April 5th, at the "Invest in China" German Special Session promotion event, the German Society for the Advancement of Sustainable Physical Technologies stunned the audience by announcing a major breakthrough - a complete set of high-performance, high-safety solid-state sodium-sulfur batteries with fully automated continuous production processes. This innovative process not only increases the energy density of batteries to an unprecedented 1000Wh/kg but also achieves a theoretical loading capacity of up to 20000Wh/kg for the negative electrode, akin to a "game-changer" in battery technology, heralding a revolutionary change in the range of electric vehicle (EV) travel.

Over the course of two years of meticulous research and development, the German research team has developed this new solid-state sodium-sulfur battery production process, cleverly combining Germany's profound expertise in high vacuum, automation, nuclear physics, and magnetic levitation. The process has made precise corrections to misconceptions in solid-state battery development and achieved multiple innovations and breakthroughs in technical shortcomings. The application of novel concepts such as ion printing and porous current collectors allows sodium-sulfur batteries to be produced fully automatically in a vacuum environment, significantly enhancing battery performance, reducing production costs, and increasing production capacity. This perfectly embodies the efficiency and intelligence features of Germany's Industry 4.0.

Focusing on the performance data generated by this process, the revolutionary significance of solid-state sodium-sulfur batteries is self-evident. With an energy density of 1000Wh/kg, it means that each kilogram of battery can store the energy equivalent of one kilowatt-hour. By extrapolation, only 100 kilograms of batteries are needed to carry 100 kilowatt-hours, and 300 kilograms of batteries are enough to support 300 kilowatt-hours. Theoretically, this could enable electric vehicles to achieve a single charge range of over 2000 kilometers, completely eliminating concerns about EV range anxiety and making long-distance driving comparable to conventional internal combustion engine vehicles, thus significantly promoting the widespread adoption of electric vehicles worldwide.

What's even more remarkable is that these batteries use solid-state sodium-sulfur technology rather than traditional lithium-ion batteries. Sodium, with its abundant reserves on Earth and wide distribution, boasts low extraction costs compared to lithium. Once solid-state sodium-sulfur batteries are mass-produced on a large scale, their cost advantages will become more apparent, potentially becoming a key factor in driving down the prices of electric vehicles and energy storage systems, accelerating the transition from fossil fuels to clean energy.

Currently, the Chinese market showcases significant diversity in the range of new energy electric vehicles. Mainstream household and urban commuting models generally offer economical range performance, with a single full charge enabling travel of approximately 300 to 400 kilometers, meeting daily commuting needs. Some compact and subcompact electric vehicles targeting the mass market have ranges between 100 and 300 kilometers, suitable for short trips within cities. However, actual range may vary due to factors such as temperature, driving style, and use of in-car electronics, with potential reductions during winter months.

On the other hand, high-end and long-range version models are dedicated to breaking the range barrier, offering nearly the same long-distance driving experience as conventional fuel-powered vehicles. By incorporating high-energy-density batteries, optimizing the efficiency of electric drive systems, and using lightweight materials, some flagship models can travel 500 to 700 kilometers on a single charge, or even claim ranges exceeding 1000 kilometers, alleviating consumer concerns about range anxiety and catering to cross-city travel or long-distance road trips. These models are equipped with fast-charging capabilities to enhance convenience for users.

Currently, the production process has completed its overall design, and the German research team is collaborating with several universities in China and Germany to establish joint research and development centers and trial production lines. It is expected that by the end of this year, equipment prototypes and battery samples will be unveiled, with mass production capacity expected by the end of next year. German experts have clearly stated their plans to cooperate deeply with industry funds and battery companies, intending to invest in building factories in China, demonstrating their high recognition of the potential of the Chinese market and manufacturing capabilities.

The research team, led by three industry authorities, Professor Flei in nuclear physics and energy, Professor Westkampbell in automated production technology, and Professor Makangkai in new materials, are all members of the Board of Directors of the German Society for the Advancement of Sustainable Physical Technologies. Such a powerful lineup of researchers provides solid assurance for the successful implementation of the project.

In conclusion, the high-performance solid-state sodium-sulfur battery production process released by the German research team not only achieves significant breakthroughs at the technical level but also, with its ultra-high energy density, rich resource base, and potential low-cost advantages, paints a hopeful picture for global green energy transition. As cooperation between China and Germany deepens, we have every reason to expect that this "Made in Germany" solid-state sodium-sulfur battery will quickly transition from the laboratory to the production line, entering millions of households and becoming a powerful engine driving the world into a clean, efficient, and sustainable energy era. This revolutionary breakthrough not only heralds a leap in the range of electric vehicles but also represents a solid step towards a green future for humanity.

Sanxin New Materials Co., Ltd. specializes in the production of high-quality ceramic milling balls, nanoparticles, nanopowders, as well as wear-resistant and abrasion-resistant ceramics. With a dedicated focus on research and development, Sanxin is at the forefront of ceramic material innovation, catering to diverse industries ranging from pharmaceuticals to electronics. Their extensive portfolio of ceramic products is renowned for its exceptional durability, precision, and performance, making Sanxin a trusted partner for companies seeking advanced material solutions.

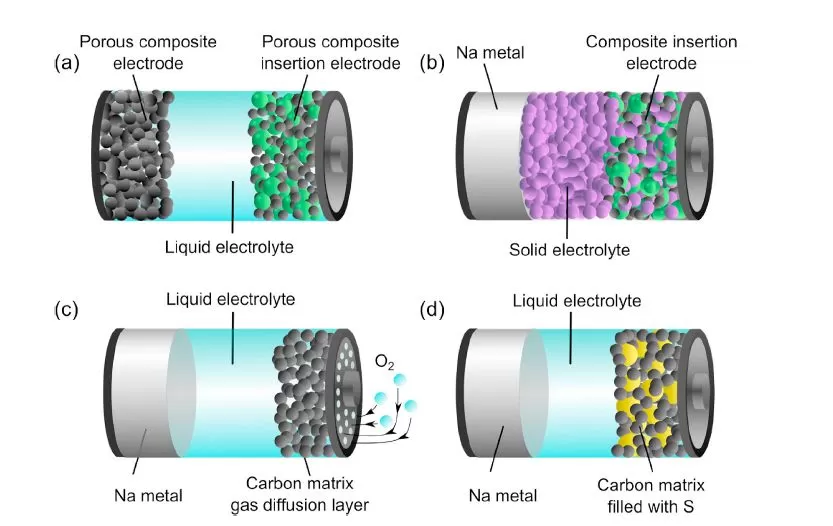

Preparation of Solid-State Electrolyte: Solid-state sodium-sulfur batteries require a solid electrolyte to facilitate the movement of sodium ions between the anode and cathode. Zirconia beads can be utilized in the preparation of solid electrolyte materials. These beads are employed in the grinding process to achieve the desired particle size and homogeneity of the solid electrolyte precursor materials, which typically include sodium-ion conductors and ceramic additives.

Electrode Fabrication: The electrodes of solid-state sodium-sulfur batteries consist of active materials such as sulfur for the cathode and sodium metal for the anode, along with conductive additives and binders. Zirconia beads can be used in the grinding process to refine the particle size of these electrode materials, ensuring uniform dispersion and optimal contact between the active materials and the electrolyte.

Enhanced Battery Performance: By facilitating the grinding process, zirconia beads help to improve the surface area and reactivity of the electrode materials, leading to enhanced battery performance. Finely ground electrode materials exhibit improved electrochemical kinetics, enabling faster ion diffusion and more efficient charge/discharge processes. This ultimately results in higher energy density, improved cycling stability, and longer battery lifespan.

Reduced Manufacturing Costs: The use of zirconia beads for grinding in the production of solid-state sodium-sulfur batteries can contribute to cost reduction by enhancing the efficiency of material processing and minimizing waste. By achieving the desired particle size and distribution of electrode and electrolyte materials, manufacturers can optimize material usage and streamline production processes.

In summary, zirconia beads from Sanxin New Materials are instrumental in the production of solid-state sodium-sulfur batteries by facilitating the preparation of solid electrolytes, refining electrode materials, and enhancing battery performance. Their role in the grinding process contributes to improved efficiency, performance, and cost-effectiveness in the manufacturing of these advanced battery systems.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder