In the ever-evolving landscape of the mining industry, where operators grapple with the relentless pressures of declining ore grades, escalating energy costs, and stringent environmental regulations, the grinding circuit emerges as a critical battleground for maintaining profitability and sustainability. Traditional steel grinding media, long regarded as the industry standard due to their robustness and low initial cost, are increasingly revealing their limitations. These include not only high energy consumption but also chemical interferences that compromise downstream processes like gold cyanidation and base metal flotation. This comprehensive paper delves into the transformative potential of advanced ceramic grinding media—encompassing nano-composite, high-alumina, and zirconia-toughened variants—as enablers of "clean grinding" technologies that address these challenges head-on.

The shift to ceramic media represents more than a mere substitution; it is a strategic overhaul that optimizes the entire mineral processing value chain. By leveraging the inherent properties of ceramics—such as superior hardness, chemical inertness, and lower density—mining operations can achieve significant reductions in power usage, media wear, and reagent consumption while enhancing metallurgical recoveries. For instance, studies have shown that ceramic media can boost gold extraction rates by up to 1.7% compared to steel, translating into substantial revenue gains for large-scale operations. Furthermore, the environmental benefits align seamlessly with global ESG (Environmental, Social, and Governance) imperatives, including reduced carbon emissions and minimized heavy metal contamination in tailings.

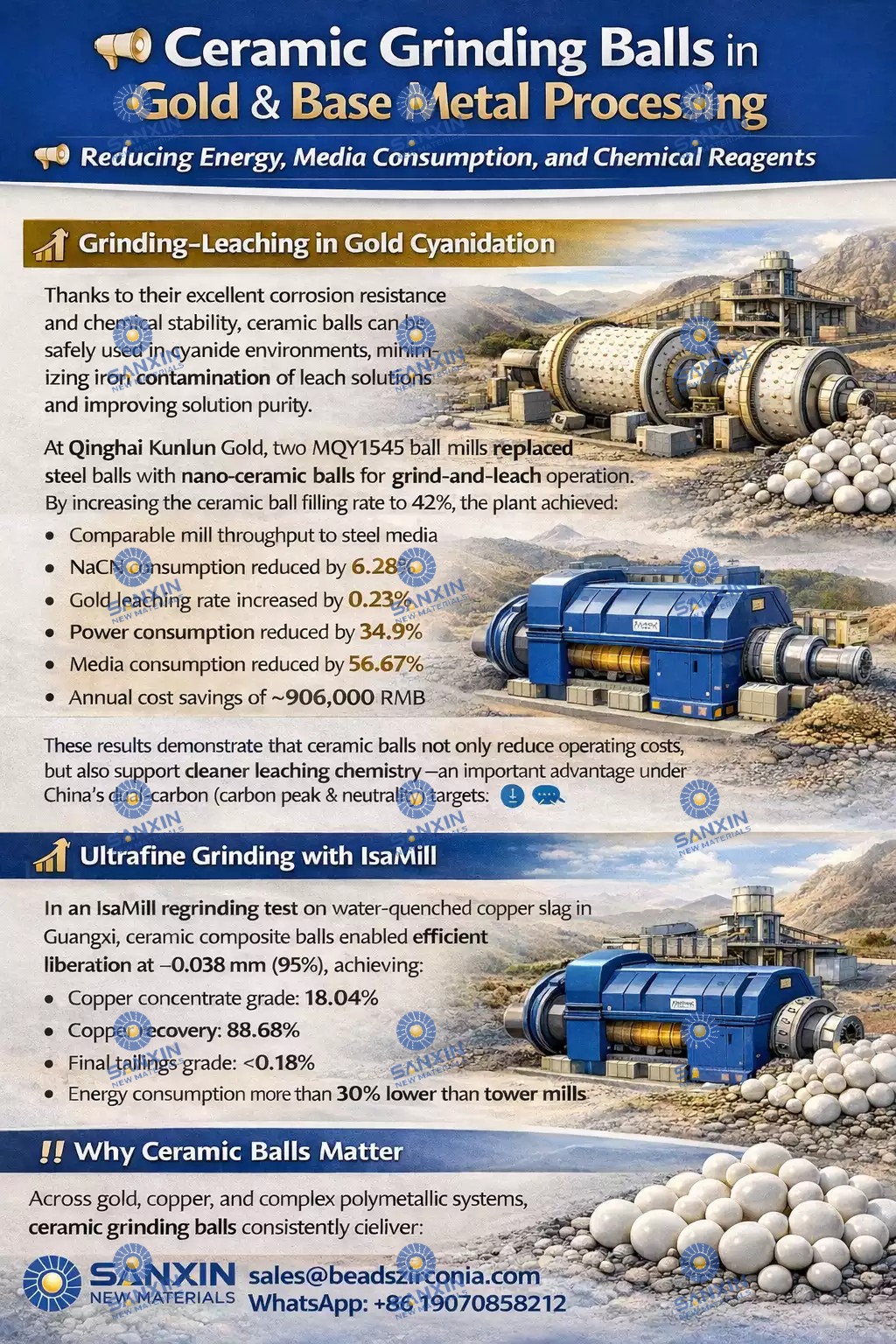

This exploration begins with the manufacturing excellence that underpins ceramic media's performance, contrasting it with the flaws of steel production. It then examines the "iron poisoning" phenomenon in gold leaching, where steel media's electrochemical activity sabotages cyanide efficiency and oxygen availability. A detailed case study from the Qinghai Kunlun Gold operation illustrates real-world impacts, including a 34.9% drop in power consumption and halved media wear rates. The paper further discusses ultrafine grinding revolutions like the IsaMill™, where ceramic media is indispensable for processing refractory ores, and analyzes how particle size distribution (PSD) improvements enhance flotation outcomes in base metals.

Beyond technical merits, the ESG advantages are profound: ceramic media supports decarbonization by slashing energy intensity by 30% or more, reduces logistical footprints, and improves water quality in processing circuits. An implementation guide provides practical steps for transitioning from steel to ceramic, emphasizing liner compatibility, filling rate adjustments, and classification tuning. Ultimately, this paper posits that adopting ceramic grinding media is not optional but a strategic necessity for the "Mine of the Future," offering economic, metallurgical, and environmental dividends that position operators for long-term success.

As the industry navigates toward net-zero goals and resource efficiency, ceramic media stands as a beacon of innovation. This analysis draws on empirical data, industry case studies, and scientific principles to equip stakeholders with the knowledge needed to evaluate and implement this shift. For those ready to act, a technical audit can unlock customized ROI projections, ensuring that the transition is both feasible and financially rewarding.

The superior performance of ceramic grinding media in mining applications is intrinsically linked to its sophisticated manufacturing process, which ensures structural integrity, uniformity, and durability far exceeding that of traditional steel media. While forged steel balls often suffer from internal voids, surface decarburization, and inconsistent hardness due to rapid cooling and hammering processes, ceramic media is meticulously engineered to eliminate such defects. This section explores the advanced production cycle of ceramic grinding media, highlighting how each step contributes to its efficacy in high-stress milling environments.

Ceramic grinding media has evolved from basic alumina balls used in the mid-20th century to today's advanced composites incorporating zirconia (ZrO₂) and silicon carbide for enhanced toughness. High-purity alumina (Al₂O₃) remains the backbone, offering a Mohs hardness of 9—comparable to sapphire—making it ideal for abrasive ores. Zirconia-toughened alumina (ZTA) adds fracture resistance, crucial for mining's impact-heavy conditions. The selection of raw materials is paramount; impurities as low as 0.1% can compromise density and wear resistance. Suppliers source bauxite-derived alumina or yttria-stabilized zirconia, ensuring compliance with ISO standards for chemical composition.

The manufacturing process is a multi-stage ordeal designed to achieve densities up to 3.9 g/cm³ and Vickers hardness exceeding 1200 HV, far surpassing steel's 700-800 HV.

Ultrafine Milling of Raw Materials: The process commences with wet milling of high-purity alumina or zirconia into a sub-micron slurry. Using attritor mills or ball mills with ceramic linings, particles are reduced to 0.1-1 μm. This step is critical: smaller initial sizes facilitate denser packing during forming, minimizing porosity in the final product. Water or organic binders are added to create a stable suspension, preventing agglomeration. Energy input here is optimized to avoid overheating, which could alter crystal structures.

Spray Drying & Granulation: The slurry is atomized in a spray dryer, where hot air (up to 300°C) evaporates moisture, yielding spherical granules with diameters of 50-200 μm. These granules exhibit excellent flowability, essential for uniform mold filling. Additives like polyvinyl alcohol (PVA) enhance binding, ensuring granules maintain shape during handling. This method contrasts with steel's melting and forging, which introduce thermal stresses.

Isostatic Pressing: For media larger than 20 mm, Cold Isostatic Pressing (CIP) applies uniform pressure (100-400 MPa) from all directions via a flexible mold immersed in hydraulic fluid. This eliminates density gradients that plague uniaxial pressing, preventing "pear-shaping" or cracking. Hot Isostatic Pressing (HIP) may follow for ultra-high-density variants, sintering under argon at 1000-2000 MPa to close any residual pores.

High-Temperature Sintering: The "green" bodies are fired in tunnel kilns at 1450-1650°C for 24-48 hours. This triggers solid-state diffusion, where atoms migrate across grain boundaries, fusing particles into a monolithic crystalline matrix. Controlled cooling prevents thermal cracking, and atmospheres (e.g., reducing for zirconia) maintain phase stability. Post-sintering, balls are polished to achieve sphericity >95% and surface roughness <0.5 μm, enhancing mill efficiency.

Rigorous testing follows: drop tests for impact resistance, abrasion tests per ASTM G65, and scanning electron microscopy (SEM) for microstructure analysis. Ceramic media's uniformity reduces breakage rates to <0.5% annually, versus steel's 2-5%. In mining, this translates to longer campaigns and fewer shutdowns. Economically, while initial costs are higher (2-3x steel), lifecycle savings from reduced consumption (up to 70%) justify the investment.

In summary, the manufacturing excellence of ceramic media—rooted in precision engineering—positions it as a superior alternative, enabling "clean" grinding that steel cannot match.

In gold mining, the grinding stage is pivotal, setting the chemical stage for cyanidation. However, steel media introduces "iron poisoning," a multifaceted issue that impairs leaching efficiency through galvanic interactions and oxygen depletion. This section dissects the mechanisms and quantifies the benefits of switching to inert ceramic media.

Steel balls, composed primarily of iron with carbon and chromium alloys, are electrochemically reactive in wet slurries. Contact with sulfide minerals like pyrite (FeS₂) or arsenopyrite (FeAsS) forms a galvanic cell: steel as the anode oxidizes, releasing Fe²⁺ ions. These ions complex with cyanide to form ferrocyanide [Fe(CN)₆]⁴⁻, sequestering up to 20% of available cyanide. The reaction is:

Fe + 2H⁺ → Fe²⁺ + H₂ (anodic)

This not only increases reagent costs but also generates iron hydroxides that coat gold particles, hindering dissolution. Studies indicate cyanide consumption rises 10-15% with steel media.

Iron oxidation consumes dissolved oxygen (DO), essential for Elsner's Equation:

4Au + 8NaCN + O₂ + 2H₂O → 4Na[Au(CN)₂] + 4NaOH

DO levels drop from 8-10 ppm to <5 ppm, slowing kinetics and necessitating extended leaching times or supplemental oxygenation, adding costs. Ceramic media, being non-metallic and inert, avoids these reactions, maintaining DO and "free" cyanide, yielding 1-2% higher recoveries.

Pre-aeration or lead nitrate addition can mitigate iron effects, but they introduce complexities. Ceramic media eliminates the root cause, reducing cyanide use by 6-10% and enhancing extraction from 93% to 95%. In refractory ores, this is transformative, as iron contamination exacerbates passivation.

The Qinghai Kunlun Gold mine in China's remote Qinghai Province exemplifies the tangible benefits of ceramic media adoption. Processing low-grade refractory gold ores, the operation faced high energy bills and suboptimal recoveries with steel media. This case study details the transition and outcomes.

The plant features two MQY1545 ball mills (1.5m diameter, 4.5m length) in a semi-autogenous grinding (SAG) configuration, targeting P80 of 75 μm for cyanidation. Baseline with steel: throughput 200 t/h, power 500 kW/mill, media consumption 0.8 kg/t.

Post-switch to high-alumina ceramic balls:

Power Consumption: Dropped 34.9% to ~325 kW/mill, due to ceramic's 3.6 g/cm³ density vs. steel's 7.8 g/cm³, allowing higher fill rates (42%) with lower torque.

Media Consumption: Reduced 56.67% to 0.35 kg/t, extending recharge intervals and cutting logistics in remote areas.

Metallurgical Recovery: Gold recovery rose 0.23% to 93.83%, adding millions in revenue for a 1 Mtpa plant at $2000/oz gold.

Cyanide Cost: Fell 6.28%, from baseline to 93.72%, via eliminated iron poisoning.

Metric | Steel Media | Ceramic Media | Economic Impact |

Media Loss | 0.8 kg/t | 0.35 kg/t | Direct OpEx Savings |

Cyanide Cost | 100% | 93.72% | Reduced Reagent Bill |

Energy Intensity | High | Low | Carbon Credit Potential |

Recovery Increase | - | +0.23% | Revenue Boost |

This transition, validated in industrial trials, underscores ceramic's viability.

With "easy" ores depleted, mining turns to refractory deposits requiring P80 <20 μm. The IsaMill™, a horizontal stirred mill, revolutionizes this, but steel media is incompatible due to heat and wear. Ceramic media enables it.

Developed in the 1990s by Glencore Technology, the IsaMill uses 1.5-6 mm ceramic media (zirconium silicate or ZTA) in a high-speed (up to 22 m/s) agitator, achieving energy efficiencies 20-40% better than vertical mills. It produces clean mineral surfaces, boosting leaching.

In regrinding copper slag, ceramic media yielded narrower PSD, liberating Cu at -0.038 mm without slimes. Steel produces over-ground fines and shards, reducing recovery by 10-15%. IsaMill installations worldwide (over 130) process 10 Mtpa, saving 2-3 kWh/t.

PSD quality—beyond average size—affects flotation efficiency. Ceramic media produces steeper curves, optimizing base metal recovery.

In Cu/Pb/Zn flotation, ideal PSD is 10-100 μm; slimes (<10 μm) hinder bubble attachment, coarses (>150 μm) sink. Ceramic's attrition grinding minimizes slimes, improving concentrate grade by 2-5% and reducing tailings losses. Absent iron coatings enhance reagent bonding.

Nano-ceramic vs. steel: chalcopyrite floatability increases 15% with ceramics.

Grinding consumes 3% of global electricity; ceramic media aids decarbonization.

Scope 2 Emissions: 30%+ power reductions lower CO₂ by 20-40% per ton.

Sustainability in Logistics: Longer life (300%) and lighter weight halve transport emissions.

Water Purity: No iron contamination simplifies treatment, supporting water reuse.

Ceramics align with "Dual-Carbon" goals, earning carbon credits.

Transition requires systems thinking.

Switch to rubber/composite liners for cushioning; steel's lifters fracture ceramics.

Increase volume to 40-45% to match charge weight: Mass = Density × Volume.

Adjust hydrocyclones for altered rheology; apex size optimization prevents over-grinding.

Pilot tests and simulations ensure smooth rollout.

Ceramic grinding media heralds a paradigm shift in comminution, delivering economic savings (20-50% OpEx), metallurgical gains (1-5% recovery), and ESG compliance. As ores complexify, adoption is imperative. Contact for audits.

Are you ready to optimize your grinding circuit? Contact our engineering team for a customized ROI projection and media wear-rate analysis.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder