In the complex world of metal mining beneficiation, the grinding process serves as a pivotal bridge between raw ore extraction and effective mineral separation. Specifically, secondary grinding and regrinding stages play a decisive role in refining ore particles from primary crushing and grinding to the precise sizes needed for efficient downstream processes like flotation, magnetic separation, or gravity concentration. These stages directly influence key outcomes such as particle size distribution, mineral liberation degree, concentrate grade, and overall recovery rates—factors that ultimately determine a mine's operational efficiency and profitability.

Traditionally, secondary grinding circuits have relied heavily on steel-based media, particularly high-chrome steel balls, valued for their robustness and impact strength. However, these conventional media come with significant drawbacks: high wear rates leading to excessive consumption, elevated energy demands, and iron contamination that can adversely affect mineral surface chemistry. In purity-sensitive applications, such as processing magnetite or sulfide ores, iron pollution from steel media can impair flotation response or magnetic separability, resulting in lower recoveries and subpar product quality.

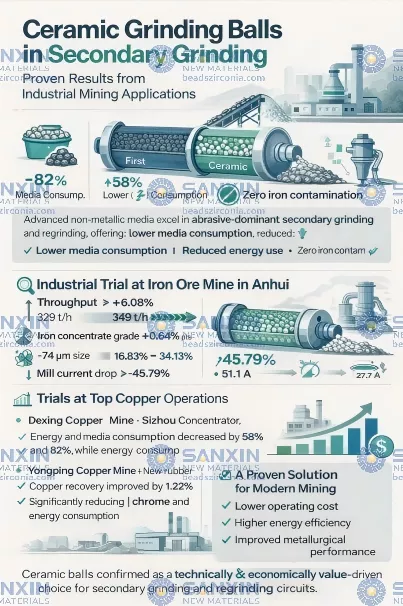

Enter ceramic grinding balls—an innovative non-metallic alternative primarily composed of high-purity alumina (Al₂O₃) or zirconia (ZrO₂), sintered at extreme temperatures to achieve exceptional hardness and durability. These balls are increasingly adopted in secondary and regrinding circuits across metal mines worldwide, offering superior wear resistance, zero iron contamination, and substantial energy savings. Extensive industrial trials, particularly in major Chinese operations, have substantiated their technical viability and delivered compelling economic returns.

Ceramic grinding balls stand out due to their engineered properties tailored for fine grinding environments:

Exceptional Wear Resistance: With Mohs hardness reaching 9 (compared to 6-7 for high-chrome steel), wear rates are dramatically lower—often 1/10 to 1/50 of steel balls. This translates to media consumption as low as 0.015-0.05 kg/t versus 0.1-1.2 kg/t for steel.

Chemical Inertness and Zero Contamination: Unlike steel, ceramics do not react with ore slurries or release iron ions, preserving mineral surface integrity crucial for flotation or magnetic separation.

Lower Density: At 3.6-4.0 g/cm³ (versus 7.8 g/cm³ for steel), ceramic balls reduce mill load, lowering power draw and enabling higher throughput or reduced energy per ton processed.

These attributes make ceramic balls particularly advantageous in secondary grinding, where tight particle size control and minimal contamination are paramount.

Secondary grinding often employs large overflow or grate discharge ball mills integrated into closed circuits with classifiers or hydrocyclones.

Ceramic balls can be deployed via full replacement or mixed with steel (commonly 7:3 ceramic-to-steel by mass). Below are detailed examples from prominent Chinese metal mines.

A major Anhui magnetite operation employing stage grinding and magnetic separation faced challenges with high-chrome steel balls in its secondary Φ4.2×13m overflow ball mill: elevated load, energy use, and fluctuating concentrate grades due to iron contamination.

A 30-day trial using a 7:3 ceramic-steel mix yielded remarkable improvements:

Throughput surge: From 329 t/h to 349 t/h (+6.08%), attributed to lower density reducing inertial resistance and improving grinding kinetics.

Finer, more uniform product: -74μm fraction increased dramatically while over-grinding (-10μm) stayed below 8%.

Grade enhancement: Iron concentrate rose 0.64% to 67.82%, thanks to eliminated iron pollution and better liberation.

Cost savings: Power draw dropped 45.79%; media consumption fell over 98% (0.015 kg/t vs. 0.8 kg/t).

This case underscores ceramic media's value in iron ores sensitive to contamination.

Metalloinvest installing 24 new magnetic separators at ...

Jiangxi Copper, a leading producer, conducted trials in several facilities processing porphyry copper ores and smelter slag.

Dexing Copper Mine (Sizhou Plant): Full ceramic replacement in a large secondary ball mill maintained target fineness (-74μm at ~45%) while slashing energy by 58% (28 to 11.76 kWh/t) and media use by 82%. Reduced reagent consumption in downstream flotation added further savings.

Yongping Copper Mine: Combining ceramic balls (6:4 mix) with high-elasticity rubber liners optimized particle distribution—boosting ideal floatable fraction to 85% and reducing over-grinding. Copper recovery improved 1.22% to 89.78%, with 42% lower energy and 75% less media consumption.

Guixi Smelter Slag Plant: On abrasive slag, a 7:3 mix cut energy 3-4 kWh/t and media 55%, while enhancing iron and copper recoveries.

Aggregated results highlight four cornerstone advantages:

Drastic Reduction in Media Consumption: Savings of hundreds to thousands of dollars annually per million tons processed.

Significant Energy Efficiency: 30-58% reductions, lowering both costs and carbon footprints.

Elimination of Iron Contamination: Directly boosts concentrate grades and recoveries by preserving mineral surfaces.

Superior Particle Size Control: Minimizes over-grinding, maximizes liberation in target size ranges.

To achieve optimal results:

Tailor replacement ratios to ore hardness (higher ceramic for softer ores).

Pair with rubber or polyurethane liners for enhanced kinetics and longevity.

Increase filling rates 3-5% and fine-tune rotational speeds to compensate for lower density.

Prioritize secondary/regrinding in contamination-sensitive ores (e.g., iron, copper, lead-zinc).

Evidence from Anhui and Jiangxi operations conclusively demonstrates that ceramic grinding balls enable throughput increases exceeding 6%, energy savings of 30-58%, media reductions up to 98%, and meaningful improvements in concentrate quality and recovery. By resolving longstanding issues with steel media, ceramics pave the way for greener, more efficient, and cost-effective beneficiation.

Looking ahead, ongoing advancements in ceramic formulations—improving toughness and thermal stability—will broaden applications to primary grinding and ultra-fine circuits. Integrated with digital monitoring and AI-driven optimization, ceramic media are poised to become the standard in modern metal mining, supporting global goals for sustainability and resource efficiency.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder