To address this question, it is essential to understand the relationship between the linear velocity of the sand mill and the grinding medium, as well as the drawbacks of excessive linear velocity in sand mills.

The higher the linear velocity, the greater the impact on the grinding medium in the sand mill, which may lead to the breakage of the chosen grinding medium.

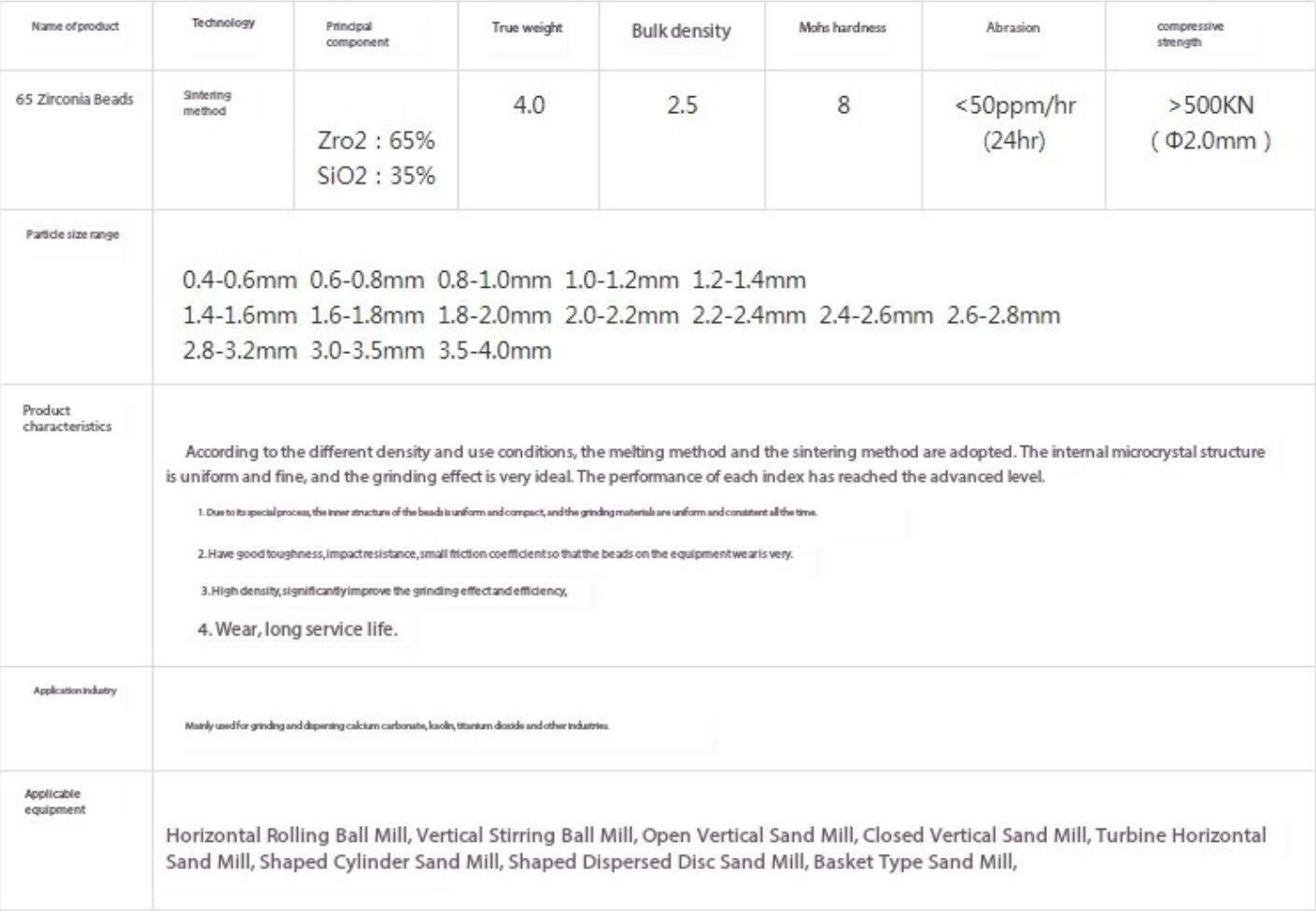

65% zirconium oxide beads belong to a type of zirconium oxide grinding ball, also known as zirconium silicate beads. Zirconium silicate beads are suitable for grinding and dispersing applications in industries such as calcium carbonate, kaolin, titanium dioxide, paint, and coatings. Compared to 95% zirconium beads, they are less wear-resistant, and 65% zirconium oxide beads are prone to breakage in sand mills with high linear velocities, such as rod-pin sand mills, which can achieve linear velocities of 11-13 m/s. In such conditions, the hardness requirements for zirconium beads are quite high, and only yttria-stabilized zirconium oxide beads can be used.

65% zirconium oxide beads can be used in disc-type sand mills since the linear velocity of disc-type mills typically ranges from 5 to 10 m/s, and at these speeds, bead breakage is unlikely.

Currently, the linear velocities of sand mills produced by various manufacturers vary, generally falling between 9-14 m/s, and their grinding efficiency also differs.

In general, vertical sand mills can use ordinary grinding media in the range of 0.1-2 mm, while horizontal sand mills commonly use grinding media in the range of 0.3-2 mm. Double-power centrifugal separation mills can use grinding media in the range of 0.03-1 mm. Choosing the right grinding beads often results in significantly improved performance. The specific matching of sand mill types and recommended grinding beads is as follows (for reference):

Vertical sand mills are recommended to use 0.10-1 mm 65% zirconium oxide beads or zirconium oxide beads.

Horizontal double-power centrifugal separation sand mills are recommended to use 0.03-1 mm zirconium silicate beads or zirconium oxide beads.

Traditional horizontal sand mills are recommended to use 0.6-3.0 mm glass beads or zirconium silicate beads.

Rod-pin horizontal sand mills are recommended to use 0.3-2.0 mm zirconium oxide beads.

Turbine horizontal sand mills are recommended to use 0.3-2.0 mm zirconium silicate beads or zirconium oxide beads.

Irregular cylinder sand mills are recommended to use 1.0-2.0 mm zirconium silicate beads.

Irregular dispersing disc sand mills are recommended to use 0.6-2.5 mm zirconium silicate beads or zirconium oxide beads.

Ring-type sand mills are recommended to use 0.4-1.5 mm zirconium oxide beads.

Double-power centrifugal sand mills are recommended to use 0.03-1 mm zirconium oxide beads.

Basket sand mills are recommended to use 1.0-3.0 mm zirconium silicate beads or zirconium oxide beads.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder