Introduction

This study explores the ultrafine grinding of Panax Notoginseng, a valuable medicinal plant. Traditional processing methods result in large particles and low active ingredient absorption. Ultrafine grinding can overcome these limitations, making it a hot topic in research. Various methods exist, but we focus on ball milling. Despite its advantages, systematic research on Panax Notoginseng ultrafine grinding using ball milling is lacking. This study employs a planetary ball mill and single-factor experiments to optimize key parameters. The findings enhance our understanding of Panax Notoginseng ultrafine grinding and provide valuable guidance for future research.

Materials and Methods

Panax Notoginseng samples were prepared from Guangdong Zhongsheng Pharmaceutical Co., Ltd., and underwent cleaning and drying. Coarse powder was obtained through primary crushing and sieving. Ultrafine grinding experiments utilized a planetary ball mill with varying mill rotation speeds, ball-to-material ratios, and milling times. Laser particle size analysis, optical microscopy, and scanning electron microscopy assessed particle size and morphology changes.

Results and Discussion

Single-Factor Experiments

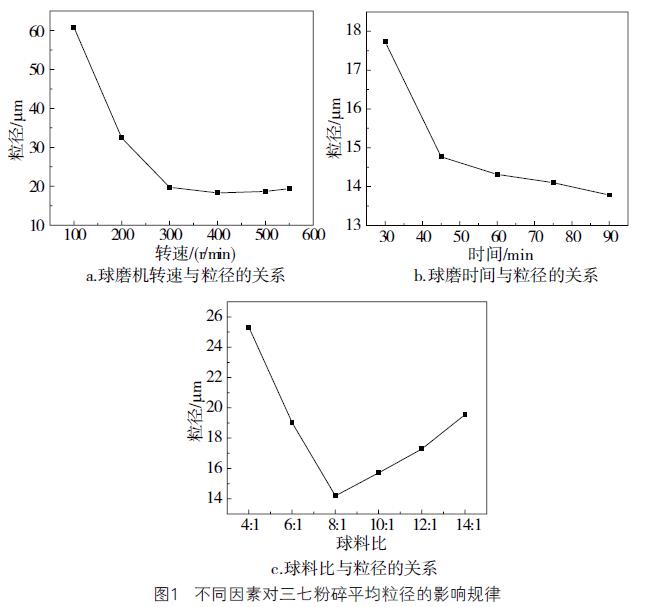

Single-factor experiments were conducted to analyze the impact of mill rotation speed, ball-to-material ratio, and milling time on average particle size. Optimal conditions were identified, balancing particle size reduction against energy consumption and temperature increase.

Statistical Analysis of Particle Size Distribution

Particle size distribution parameters were evaluated, including volume and surface area average particle sizes (D[4,3] and D[3,2]), median size (D(50)), and boundary sizes (D(10) and D(90)). Span, which measures distribution width, was also considered. Group 11 emerged as the optimal choice, featuring uniform particle distribution, smaller particle sizes, and improved symmetry.

Regression Equations and Parameter Optimization

Statistical analysis yielded a mathematical model linking ultrafine Panax Notoginseng particle size to mill rotation speed, ball-to-material ratio, and milling time. Interaction between milling time and mill rotation speed was significant. Optimal parameters were identified as a mill rotation speed of 500 r/min, a ball-to-material ratio of 8, and a milling time of 90 minutes. Under these conditions, Panax Notoginseng exhibited a uniform particle size distribution with an average particle size of 11.992 μm, achieving the desired ultrafine state.

Conclusion

This study advances Panax Notoginseng ultrafine grinding by optimizing key parameters using a planetary ball mill. Optimal conditions were established, enhancing our understanding of the ultrafine grinding process. A mathematical model was developed, revealing significant interactions between milling time and mill rotation speed. These findings offer valuable guidance for further research, potentially improving the utilization of Panax Notoginseng in various applications.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder