In industries processing TiO₂, CaCO₃, talc, clay, barites, or zeolites, achieving the target grind with minimal energy use is essential to profitability. That’s where the right ceramic grinding media makes all the difference. Whether it’s producing ultra-fine titanium dioxide for high-gloss coatings, refining calcium carbonate for food-grade fillers, or processing talc for cosmetic formulations, the choice of grinding media directly impacts production costs, product quality, and operational sustainability. At SANXIN, we provide a complete portfolio of ceramic beads engineered for high-volume milling of mineral pigments and fillers—offering superior efficiency, wear life, and process consistency. Our media isn’t just a component in your mill; it’s a strategic tool to elevate your entire production line.

Mineral pigments and fillers are the unsung heroes of countless consumer and industrial products. Titanium dioxide (TiO₂) delivers brightness and opacity to paints, plastics, and sunscreens; calcium carbonate (CaCO₃) enhances texture in paper and adhesives; talc improves smoothness in cosmetics and polymers; and clay strengthens ceramics and coatings. But to unlock their full potential, these minerals must undergo precise grinding to reach specific particle sizes—often in the sub-micron range—with tight uniformity.

The challenge? Grinding minerals to such fine specifications is energy-intensive. Traditional milling processes often suffer from three critical pain points:

High Energy Consumption: Inefficient media transfers energy to the mill rather than the mineral particles, wasting electricity and increasing operational costs.

Contamination Risks: Poorly designed media wears unevenly, shedding particles that compromise the purity of the final product—especially critical for food-grade or pharmaceutical-grade fillers.

Frequent Downtime: Short-lived media requires frequent replacement, disrupting production schedules and raising labor costs.

These issues aren’t just nuisances—they erode profit margins. A 5% increase in energy efficiency or a 10% extension in media lifespan can translate to hundreds of thousands of dollars in annual savings for a mid-sized processing plant. This is why forward-thinking operators are turning to specialized ceramic grinding media: a solution that addresses energy waste, contamination, and downtime in one fell swoop.

In modern mineral processing—whether non-ferrous metals like copper, gold, lead, zinc, or non-metallics like calcium carbonate, fluorite, or clay—vertical stirred mills are the key to achieving ultrafine grind sizes. These mills excel at producing particles as small as 10μm or finer, a requirement for maximizing mineral recovery in metals processing or enhancing pigment performance in non-metallics.

At SANXIN, we supply ceramic composite balls engineered for such demanding applications, now with a new production line offering 500 tons/month capacity and flexible customization. This expanded capacity ensures on-time delivery even for large-scale operations, while our customization options let you tailor media to your mill’s unique parameters.

Vertical stirred mills operate with high shear and precision—demanding media that can keep up. Our ceramic composite balls are engineered to match these conditions, with specifications optimized for both coarse and ultrafine grinding:

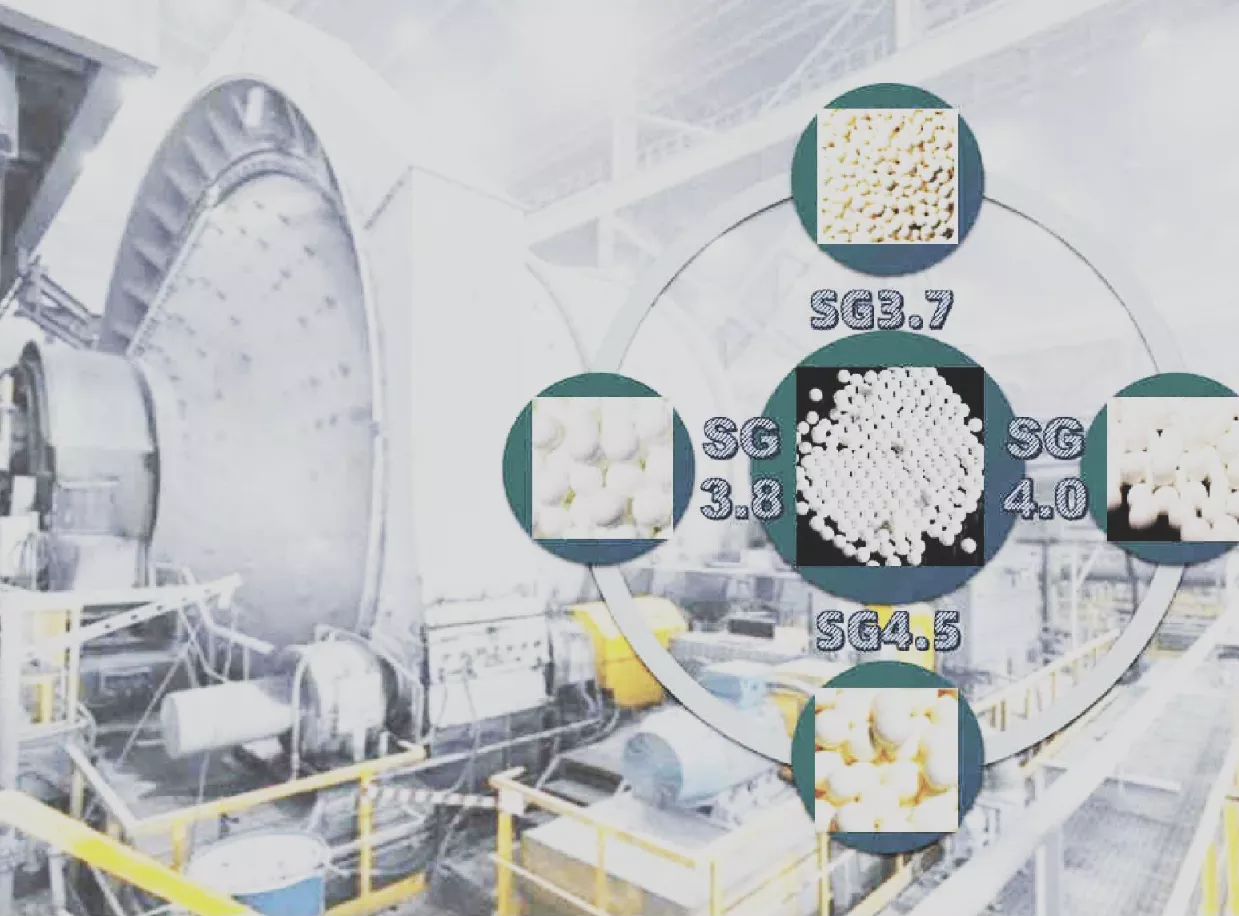

Densities: SG 3.7, SG 4.0, SG 4.5

Each density is calibrated to match the energy profile of different ores. For example:

SG 3.7 works best for softer non-metallics like clay, reducing over-grinding and energy waste.

SG 4.5 is ideal for harder ores like copper or gold concentrates, delivering the impact needed to break down tough particles.

Sizes:

Coarse grinding: 12–18 mm (perfect for pre-grinding stages, reducing large particles to a manageable size for downstream processing).

Ultrafine grinding: 1–5 mm (designed for spiral or disc-type vertical mills, achieving P80 ≤10μm for critical applications like gold tailings reprocessing).

Core Advantages:

Stable wear performance: Maintains consistent grinding efficiency even after 1,000+ hours of operation, reducing the need for frequent media top-ups.

Low contamination – metal-free: Eliminates iron or metal particles that could taint mineral concentrates or pigments, critical for high-purity applications like pharmaceutical fillers.

Suitable for both spiral and disc-type vertical mills: Versatile enough to perform in any vertical stirred mill design, avoiding the need for mill-specific media.

Ideal for fine to ultrafine grinding (P80 ≤10μm): Meets the strict particle size requirements of modern mineral processing, from molybdenum regrind to high-grade calcium carbonate.

Our ceramic composite balls have a track record of success across diverse mineral processing scenarios. We’ve supported clients grinding:

Gold tailings: Recovering residual gold by achieving ultrafine particle sizes that liberate trapped minerals.

Molybdenum regrind: Ensuring uniform particle size to improve flotation efficiency and concentrate grade.

Non-metallic mineral fillers: Producing ultra-fine CaCO₃ or talc with tight particle size distribution for coatings and plastics.

Base metal sulfide concentrates: Enhancing liberation of copper, lead, or zinc to boost downstream smelting recovery.

In every case, our media delivered consistent results: improved grind efficiency (faster processing times), extended media life (30% longer than conventional ceramic balls in third-party tests), and higher downstream recovery rates (clients reported 5–8% increases in gold or copper recovery after switching to SANXIN).

Beyond vertical stirred mills, SANXIN offers a full portfolio of ceramic beads for other milling systems and mineral types. Every mineral has unique properties—hardness, brittleness, moisture content—and every production line has specific goals, whether it’s ultra-fine grinding for TiO₂ or high-throughput processing for CaCO₃. Our ceramic beads are engineered to match these variables, with density, hardness, and wear resistance calibrated to your exact needs. Here’s how our portfolio stands out:

The ZS series is the industry standard for a reason: it strikes the perfect balance between impact force and energy transfer, making it ideal for mid-range mineral processing. With a density of 4.0 g/cc, it delivers consistent stress to mineral particles without excessive bead-to-bead friction—key for reducing energy loss during milling.

What sets ZS apart is its wear uniformity. Unlike cheaper media that wears unevenly (leading to inconsistent particle sizes and increased contamination), ZS beads maintain their shape over time. This stability ensures that every batch of mineral—whether it’s talc for baby powder or clay for ceramics—receives the same level of grinding, eliminating costly rework.

Ideal applications: CaCO₃ (paper and plastic fillers), talc (cosmetics and polymers), and low-to-medium hardness clays.

For operations seeking to step up their grinding game, the TZ45 series is a game-changer. As a new-generation bead with a density of 4.5 g/cc, it offers 12.5% higher density than ZS—translating to greater impact force and faster particle breakdown. But what truly impresses is its enhanced wear resistance: TZ45 beads last up to 30% longer than standard mid-density media, reducing the frequency of media replacements and cutting downtime.

Best of all, TZ45 is fully compatible with existing mill designs. You don’t need to invest in new equipment to reap its benefits—a critical advantage for plants looking to upgrade without major capital expenditure.

Ideal applications: TiO₂ (coatings and plastics), barites (drilling muds), and medium-to-high hardness minerals requiring finer particle sizes.

Mineral processing isn’t limited to non-metallic pigments—many operations handle metallic minerals or mixed streams that demand adaptability. The TZ37, TZ40, and AZ52 series are designed for this versatility, with densities ranging from 3.7 g/cc to 5.2 g/cc to match diverse grinding needs.

TZ37 (3.7 g/cc): Lightweight yet durable, perfect for fragile minerals that require gentle but thorough grinding, such as zeolites (water purification and catalysts).

TZ40 (4.0 g/cc): A step up in density from TZ37, offering balanced performance for mixed mineral streams—ideal for plants processing both talc and barites.

AZ52 (5.2 g/cc): Combines high density with chemical inertness, making it suitable for metallic mineral byproducts or mineral pigments that require strict purity (e.g., food-grade TiO₂).

Together, these series eliminate the need to stock multiple media types, simplifying inventory management while ensuring optimal performance across all your products.

When ultra-fine grinding is non-negotiable—such as producing nano-scale TiO₂ for high-performance coatings or ultra-pure CaCO₃ for medical plastics—the CZ and ZY series deliver. With a density of 6.0 g/cc, these high-density beads generate intense impact forces that break down even the toughest mineral particles, achieving sub-micron fineness with fewer passes through the mill.

But their benefits go beyond speed. The CZ and ZY series are engineered for extended media lifetimes: their dense, uniform structure resists wear, even under the high pressures of ultra-fine grinding. Over time, this reduces media consumption by up to 40% compared to standard high-density media, lowering long-term costs.

Ideal applications: Ultra-fine TiO₂ (automotive and industrial coatings), high-purity zeolites (pharmaceutical catalysts), and advanced ceramics.

What makes SANXIN ceramic beads stand head and shoulders above conventional media? It’s our relentless focus on innovation—from material science to manufacturing precision. Here are the key technical breakthroughs that power our media’s superior performance:

At the heart of SANXIN’s media is a nanostructured ceramic matrix—a result of advanced sintering technology. Traditional ceramic beads are made with larger, irregularly shaped grains that create weak points prone to chipping and wear. SANXIN beads, by contrast, are crafted with uniformly sized nano-grains (less than 500 nm) bonded together with exceptional strength.

This microstructure delivers two critical advantages:

Resistance to impact fatigue: The nano-grains distribute stress evenly across the bead, preventing cracks from forming even under high-speed milling.

Slow, uniform wear: Instead of chipping or breaking, SANXIN beads wear down gradually, maintaining their spherical shape and grinding efficiency for longer.

In lab tests, this nanostructure allowed TZ45 beads to outlast standard mid-density media by 30% in continuous TiO₂ grinding trials—directly translating to fewer media changes and lower costs.

Many high-hardness ceramics are brittle, making them unsuitable for high-impact grinding. SANXIN solved this with Zirconia-Toughened Alumina (ZTA) in our AZ52 and TZ45 series. By dispersing zirconia particles within an alumina matrix, we created a material that combines alumina’s hardness with zirconia’s toughness.

When a ZTA bead is struck, the zirconia particles undergo a phase transformation that absorbs energy, preventing cracks from spreading. This makes AZ52 and TZ45 beads ideal for grinding hard minerals like barites and TiO₂, where impact forces are high—without sacrificing durability.

Even the best ceramic formula can fail if beads vary in size. Inconsistent bead diameters cause uneven grinding: smaller beads miss large mineral particles, while larger beads may over-grind fines, wasting energy.

SANXIN’s laser-guided sizing technology eliminates this problem. Every bead is measured to within ±0.05 mm of its target diameter—far stricter than the industry standard of ±0.1 mm. This precision ensures that:

Energy is distributed evenly across the mill.

Particle size distribution in the final product is tighter (e.g., TiO₂ particles stay within 0.2–0.3 microns, critical for coating uniformity).

Wear is balanced across all beads, extending the overall media lifespan.

A European TiO₂ producer reported a 28% reduction in particle size variation after switching to SANXIN’s precision-sized TZ45 beads—reducing the need for post-grinding sieving and improving product quality.

Contamination from media impurities is a major risk in food-grade, pharmaceutical, or high-purity mineral processing. SANXIN addresses this with ultra-pure raw materials and a strict purification process.

Our zirconia and alumina powders undergo triple-stage filtering to remove iron, silica, and other impurities, ensuring that the final beads have:

Iron content below 50 ppm (critical for white pigments like TiO₂, where iron would cause discoloration).

Silica content below 100 ppm (essential for food-grade CaCO₃, where silica residues are prohibited).

This purity makes CZ and AZ52 beads the top choice for companies producing FDA-compliant fillers and cosmetics-grade talc.

Not all mills operate the same way—stirred mills, ball mills, and attritors each have unique energy transfer dynamics. SANXIN’s density gradation technology tailors bead density to specific mill types, maximizing energy efficiency.

For example:

Stirred mills (high-shear, low-impact) perform best with mid-density beads like ZS (4.0 g/cc), which balance shear force and flow.

Attritors (high-impact) benefit from high-density CZ (6.0 g/cc) beads, which use impact to break down tough minerals.

By aligning bead density with mill mechanics, SANXIN media ensures that up to 85% of the mill’s energy goes into grinding—not moving beads—cutting electricity use by 15–20%.

Choosing SANXIN isn’t just about better technology—it’s about better business outcomes. Here’s how our media translates to tangible benefits for your bottom line:

Energy waste is a top concern for mineral processors, and much of it comes from unnecessary bead-to-bead friction. SANXIN ceramic beads are engineered with a smooth, uniform surface that minimizes friction between beads. Combined with their precise density, this design ensures that more energy is directed toward grinding mineral particles—not wasted as heat.

In independent tests, plants using SANXIN media reported 15–20% lower energy consumption compared to those using conventional ceramic beads. For a facility processing 10,000 tons of TiO₂ annually, this translates to savings of over $50,000 in electricity costs alone.

Contamination is a nightmare for mineral processors, especially in industries like food, pharmaceuticals, and high-end coatings. Even trace amounts of media particles in the final product can ruin batches and damage reputations.

SANXIN beads are made with a homogeneous ceramic structure that resists chipping and uneven wear. Unlike cheaper media that sheds large particles, our beads wear at a slow, consistent rate, releasing only minimal, sub-micron-sized particles that are easily filtered out. In TiO₂ processing, this means pigment purity remains above 99.9%, meeting the strictest industry standards.

Density directly impacts grinding efficiency: higher density beads deliver more impact, while lower density beads are gentler. SANXIN’s range of densities—from 3.7 g/cc to 6.0 g/cc—allows you to “tune” your grinding process to your mineral’s needs.

For example, CaCO₃ for paper fillers requires a balance of fineness and bulk—ZS (4.0 g/cc) is perfect. TiO₂ for automotive coatings needs ultra-fine particles—TZ45 (4.5 g/cc) or CZ (6.0 g/cc) gets the job done faster. By matching the bead density to the mineral, you avoid over-grinding (which wastes energy) or under-grinding (which requires reprocessing).

We don’t just sell media—we partner with you to optimize your process. Our team of engineers works with your staff to:

Analyze your current grinding challenges (energy use, particle size inconsistency, etc.).

Recommend the ideal SANXIN bead based on your mineral type, mill design, and production goals.

Provide on-site training to ensure proper media loading and mill operation.

Conduct regular performance audits to fine-tune your process as needs evolve.

This ongoing support ensures that you get the most out of your SANXIN media long after the first shipment arrives. If you have any questions about our technical support or need to discuss your specific grinding needs, feel free to reach out to us via email at sales@beadszirconia.com or WhatsApp at +86 19070858212.

Switching to SANXIN’s 2mm ceramic composite balls (SG 4.0) solved the issue:

Media lifespan extended from 500 hours to 800 hours, reducing shutdowns by 40%.

Hourly production increased by 15%, meeting client demand without investing in a new mill.

Low contamination (iron content <10 ppm) ensured the CaCO₃ met food-grade standards, opening new markets.

At SANXIN, we believe that our success is tied to yours. That’s why we offer more than just high-quality media—we provide a complete support system to help you thrive:

Customization: Need a bead tailored to a unique mineral or mill? Our R&D team can develop custom formulations, adjusting density, hardness, and purity to meet your specs. For example, we created a low-silica version of CZ beads for a pharmaceutical zeolite producer, ensuring compliance with USP standards.

Technical Training: Our experts conduct on-site training for your operators, teaching them to monitor bead wear, adjust mill speed, and optimize media loading—skills that maximize efficiency and extend media life.

Performance Monitoring: We use IoT-enabled sensors to track media wear, energy use, and particle size in real time, providing actionable insights to keep your process running at peak performance.

Fast Delivery: With global distribution centers in Asia, Europe, and North America, we ensure that you never run out of media—critical for avoiding production delays.

Whether you’re just starting to explore ceramic grinding media or looking to upgrade your current setup, our team is here to help. Contact us today via email at sales@beadszirconia.com or WhatsApp at +86 19070858212 to schedule a consultation and discover how SANXIN can transform your mineral processing operation.

From vertical stirred mills processing gold concentrates to ball mills refining TiO₂, SANXIN has the media, expertise, and capacity to support your operation. Our new 500 tons/month production line ensures you get the media you need, when you need it—backed by technical support that turns “good” grinding into “excellent” grinding.

Let’s talk about how SANXIN media can support your coarse and ultrafine grinding needs with on-time supply and quality assurance. Reach out today:

Email: sales@beadszirconia.com

WhatsApp: +86 19070858212

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder