The mining industry faces relentless challenges from wear and abrasion, especially in high-impact environments such as iron ore processing. As mines scale up and operational demands intensify, the limitations of traditional wear liner technologies—such as steel and small-format ceramics—become increasingly evident. The need for larger, more complex liners with tighter tolerances and enhanced durability is driving innovation across materials science, manufacturing, and installation practices.

SANXIN has emerged as a global leader by developing large-format alumina ceramic liners, integrating advanced ceramic processing with proprietary rubber vulcanization. This white paper explores the technical, operational, and economic dimensions of this breakthrough, providing a detailed look at the innovations, processes, and real-world results that set SANXIN’s solutions apart.

Introduction: The Challenge of Wear in Modern Mining

The Evolution of Wear Liner Technology

The Case for Large-Size Ceramic Liners

SANXIN’s Full-Chain Technical Control

Powder Production and Quality

Advanced Forming and Sintering

Ultra-Precision Machining

Rubber Vulcanization: The Key to Impact Resistance and Sealing

The Science of Vulcanization

SANXIN’s Proprietary Rubber Formulas

Minimizing Joint Gaps and Seams

Engineering for Complexity: Meeting the Demands of Modern Mining

Large Sizes and Complex Shapes

Tighter Tolerances

Field Customization

Proven Performance: Case Studies and Field Data

Iron Ore Processing Plants

Other Mining Applications

Comparative Wear Life and Downtime

Economic and Operational Benefits

Cost of Ownership Analysis

Maintenance and Downtime Reduction

Safety and Environmental Impact

The Future of Wear Protection: Trends and Directions

Digitalization and Smart Liners

Sustainability and Circular Economy

Next-Generation Materials

Conclusion: The SANXIN Advantage

Frequently Asked Questions (FAQ)

Contact Information

Mining is an industry defined by extremes—massive equipment, abrasive materials, high impact, and unforgiving environments. Nowhere are these extremes more apparent than in the wear and tear experienced by processing equipment. Chutes, hoppers, transfer points, and mill linings are all subject to relentless abrasion and impact from ore, rock, and slurry.

Wear liners are the first line of defense. Their performance directly affects plant uptime, maintenance costs, and overall productivity. As ore grades decline and throughput increases, the demands on wear liners have never been greater. The industry’s shift toward larger equipment and higher-capacity plants has created a need for liners that are not only more durable, but also larger, more complex, and more precisely engineered.

Historically, steel plates and rubber sheets were the materials of choice for wear protection. Steel offered good impact resistance but was prone to rapid abrasion and required frequent replacement. Rubber, while effective at absorbing impact, lacked the hardness needed for abrasive wear and could degrade under certain chemical conditions.

The introduction of ceramic liners—particularly those made from alumina (Al₂O₃)—marked a significant advance. Ceramics offered:

Exceptional hardness (Mohs 9+)

Outstanding abrasion resistance

Good chemical inertness

However, early ceramic liners were often limited in size and shape, making them difficult to install in large or complex equipment. The challenge of bonding ceramics to metal or rubber substrates, and ensuring impact resistance, further limited their adoption in some high-impact environments.

As mining operations grew in scale, so did the need for large-format liners capable of covering more area with fewer seams, reducing installation time, and improving performance. Complex geometries—curves, angular bends, and custom fits—became necessary to match the contours of modern equipment.

Traditional manufacturing and installation methods struggled to keep up. Liners were often limited to small, flat tiles, leading to excessive seams, increased risk of material buildup, and higher maintenance.

Fewer seams: Large liners cover more area, reducing the number of joints where material can accumulate or wear can initiate.

Custom fit: Complex shapes and tight tolerances ensure a better match to equipment, improving performance and reducing installation time.

Enhanced durability: Larger, well-bonded liners distribute impact and stress more effectively, extending service life.

Producing large, complex ceramic liners is not simply a matter of scaling up. Ceramics are inherently brittle and prone to cracking during forming, sintering, and handling. Achieving the necessary dimensional stability, mechanical strength, and surface quality at large sizes requires advanced materials processing and precision engineering.

SANXIN’s approach to large-size ceramic liners is built on full-chain technical control—from raw material synthesis to final machining and assembly. This vertical integration is key to achieving the quality, consistency, and performance required for demanding mining applications.

In-house alumina powder production:

SANXIN operates advanced ball milling and spray granulation systems to produce its own alumina powder. This allows for:

Strict control of particle size distribution

High purity (≥99.5% Al₂O₃)

Consistent morphology and flowability

Quality assurance at the source:

Each batch is tested for chemical composition, particle size, and impurity levels. This ensures that every liner starts with the best possible material foundation.

Large-scale isostatic pressing:

Isostatic presses apply uniform pressure from all directions, enabling the formation of large, crack-free green bodies with consistent density.

High-tonnage dry pressing:

For certain shapes and sizes, dry pressing provides high throughput and excellent dimensional control.

Flexible kiln infrastructure:

SANXIN operates a variety of kilns—gas, shuttle, and vacuum sintering—allowing precise control over temperature profiles and atmospheres. This is critical for:

Achieving full densification without warping or cracking

Tailoring microstructure for optimal wear and impact resistance

CNC grinding and polishing:

After sintering, liners are machined to final dimensions using advanced CNC equipment. This enables:

Tolerances within ±0.005 mm

Smooth surfaces for optimal fit and reduced friction

Wire-cutting and ceramic engraving:

Complex shapes, curves, and angular bends are achieved using specialized machining techniques, ensuring that even the most demanding specifications can be met.

Vulcanization is the process of chemically bonding rubber to ceramic or metal substrates using heat, pressure, and curing agents. The result is a composite liner that combines the hardness and wear resistance of ceramic with the impact absorption and sealing properties of rubber.

Custom rubber compounds:

SANXIN maintains a comprehensive database of rubber formulations, allowing liners to be tailored for specific operating conditions (impact, abrasion, temperature, chemicals).

Parameter optimization:

Each batch is optimized for adhesion strength, elasticity, and durability, ensuring a strong, uniform bond between ceramic and rubber.

One-piece vulcanization:

By vulcanizing liners as a single unit, SANXIN minimizes seams and joint gaps, reducing the risk of material buildup, water ingress, and premature wear.

Precision molding:

Custom molds and controlled curing parameters ensure that liners fit precisely to equipment contours, even in areas with curves and angular bends.

Field-proven sealing:

The result is a liner with superior sealing performance, lower maintenance requirements, and longer service life.

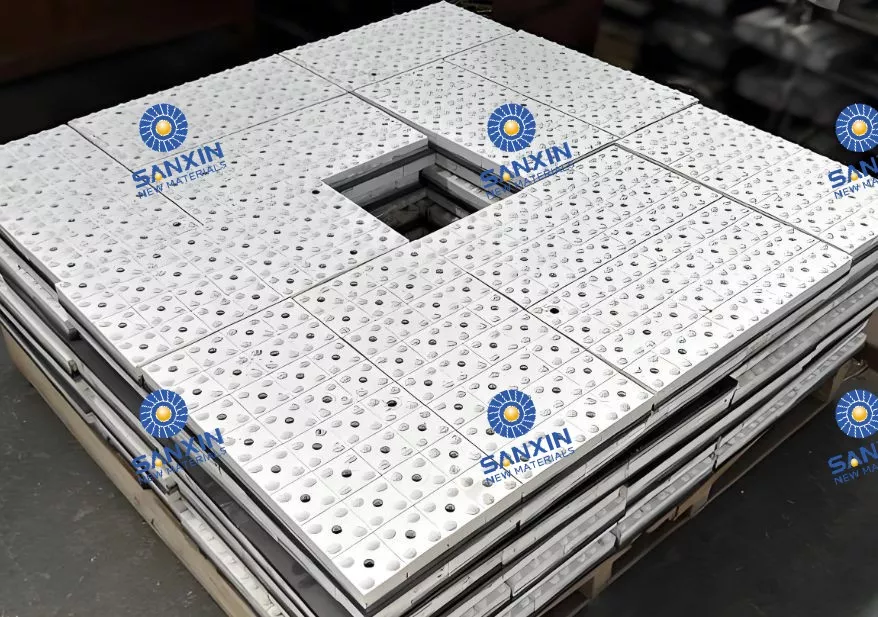

Liners up to 900×600 mm:

SANXIN can produce liners in sizes previously considered unattainable for ceramics, enabling coverage of large surface areas with fewer pieces.

Custom geometries:

Advanced forming, machining, and vulcanization techniques allow for the creation of liners with curves, bends, and intricate profiles to match the most complex equipment designs.

Precision engineering:

Tolerances within ±0.005 mm are routinely achieved, ensuring a snug fit and consistent performance.

Reduced installation time:

Precise liners are easier and faster to install, reducing plant downtime and labor costs.

On-site measurement and fitting:

SANXIN offers field measurement and customization services, ensuring that liners are perfectly matched to each installation.

Rapid prototyping:

For new or unique equipment, SANXIN can quickly develop prototypes and iterate designs based on customer feedback.

Case Study: Major Iron Ore Producer

Challenge:

Frequent liner failure and downtime in high-impact transfer chutes, leading to lost production and high maintenance costs.

Solution:

Installation of SANXIN’s large-format alumina ceramic liners with one-piece rubber vulcanization.

Results:

Wear life extended by over 30% compared to previous steel/rubber liners

Downtime reduced by 40% due to fewer replacements and faster installation

Improved material flow with minimal buildup at seams

Gold, copper, and coal plants:

SANXIN liners have demonstrated similar benefits in a range of mining environments, including improved resistance to both impact and abrasion.

Bulk material handling:

Applications in conveyors, hoppers, and feeders have shown reduced maintenance and longer intervals between shutdowns.

| Liner Type | Average Wear Life | Downtime (per year) | Maintenance Cost |

|---|---|---|---|

| Standard Steel | 6-12 months | High | High |

| Rubber-Only | 9-15 months | Moderate | Moderate |

| Small-Format Ceramic | 12-18 months | Moderate | Moderate |

| SANXIN Large-Format Ceramic | 18-24+ months | Low | Low |

Lower replacement frequency:

Longer wear life means fewer liner changes, reducing both material and labor costs.

Reduced inventory:

Fewer, larger liners simplify inventory management and reduce storage requirements.

Improved plant availability:

Less downtime translates directly to higher throughput and revenue.

Faster installation:

Large, precisely fitted liners are quicker to install, minimizing shutdown time.

Lower risk of emergency repairs:

Superior durability and sealing reduce the likelihood of unexpected failures.

Simplified maintenance planning:

Predictable wear rates and longer intervals between replacements make maintenance scheduling easier.

Safer working conditions:

Reduced frequency of liner changes means fewer opportunities for worker exposure to hazardous environments.

Lower environmental footprint:

Longer-lasting liners generate less waste and require less frequent disposal.

Embedded sensors:

Future liners may incorporate sensors to monitor wear, temperature, and impact in real time, enabling predictive maintenance.

Data-driven optimization:

Integration with plant control systems will allow for continuous optimization of liner performance and replacement schedules.

Recyclable materials:

SANXIN is exploring options for recycling spent ceramics and rubber, reducing environmental impact.

Energy-efficient manufacturing:

Advances in kiln technology and process optimization are lowering the energy footprint of liner production.

Hybrid ceramics:

Research into new ceramic compositions and hybrid materials promises even greater wear and impact resistance.

Advanced bonding technologies:

New adhesives and interlayer materials may further enhance the bond between ceramic and rubber, improving performance in extreme conditions.

SANXIN’s large-format alumina ceramic liners, enabled by full-chain technical control, advanced forming and machining, and proprietary rubber vulcanization, represent a new standard in wear protection for the mining industry. These innovations deliver:

Longer wear life

Tighter tolerances and custom fit

Reduced maintenance and downtime

Proven performance in the world’s toughest environments

By partnering with SANXIN, mining operations can achieve higher productivity, lower costs, and enhanced safety—today and into the future.

Q1: What is the maximum size and complexity SANXIN can produce?

A: SANXIN routinely manufactures liners up to 900×600 mm, including complex curves and angular bends. Custom shapes and sizes are available upon request.

Q2: Are SANXIN liners compatible with all types of mining equipment?

A: Yes. Our liners can be customized for chutes, hoppers, transfer points, mills, and more. We offer field measurement and fitting services for unique applications.

Q3: How does SANXIN ensure the quality of its liners?

A: We control every step, from powder production to final machining. Each liner undergoes rigorous inspection for dimensions, bonding strength, and surface quality.

Q4: What is the typical lead time for large-format liners?

A: Lead times vary by size and complexity but are generally 4-8 weeks from order to delivery.

Q5: Can SANXIN assist with liner installation?

A: Yes. We offer technical support, installation training, and on-site supervision to ensure proper fit and performance.

Ready to upgrade your mine’s wear protection?

Contact SANXIN to discuss your application, request technical data, or arrange a site visit.

Email: sales@beadszirconia.com

Website: www.beadszirconia.com

WhatsApp/Phone: +86-19070858212

SANXIN is a global leader in advanced ceramic materials and wear solutions, serving mining, energy, chemical, and heavy industry customers worldwide. With a commitment to innovation, quality, and customer service, SANXIN delivers next-generation products that set new standards for performance and reliability.

This white paper is intended for engineers, plant managers, procurement specialists, and industry professionals seeking to understand and address the challenges of wear in modern mining operations. For technical support, custom quotations, or further information, please contact our team directly.

SANXIN: Engineering the Future of Wear Protection.

Experience the difference with large-format ceramic liners—precision, durability, and performance you can trust.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder