The global demand for ultrafine and nanomaterials is reshaping the landscape of advanced manufacturing. From lithium-ion batteries powering electric vehicles to high-performance ceramics in electronics, the need for ever-finer, purer, and more consistent powders is accelerating. At the heart of this transformation lies the technology of wet ultrafine grinding—a process that depends not only on the sophistication of bead mills but also, crucially, on the quality and size of the grinding media.

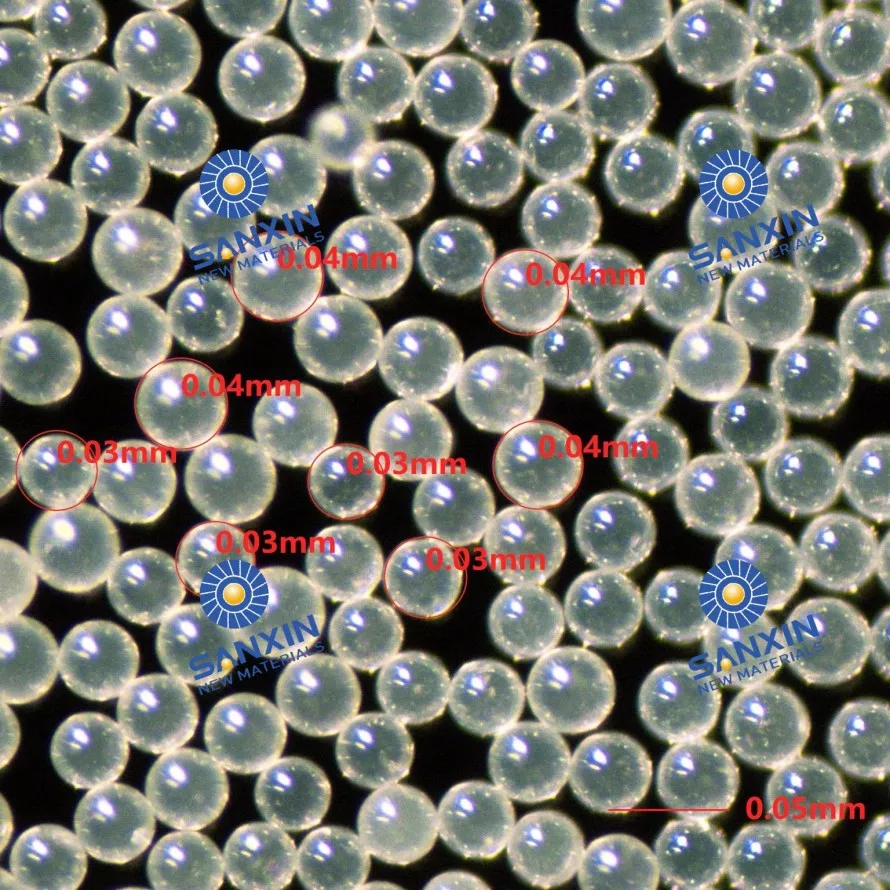

SANXIN, a leader in advanced ceramic materials, has achieved a breakthrough by reliably manufacturing and deploying 0.03mm zirconia beads for wet ultrafine grinding. This achievement sets a new industry benchmark, overcoming longstanding technical barriers and opening new possibilities in nanomaterial production, pharmaceutical dispersions, electronic inks, and beyond.

This white paper explores the significance of this milestone, delves into the science and engineering behind ultrafine grinding, examines the rigorous testing and validation of SANXIN’s microbeads, and highlights the transformative impact on key industries.

Introduction

The Science of Wet Ultrafine Grinding

Principles and Mechanisms

The Role of Bead Size

Zirconia Beads: The Gold Standard

Material Properties

Challenges at the Micro Scale

Breaking the 0.03mm Barrier: Why It Matters

Theoretical Advantages

Practical Implications

The Water Milling Test: Ensuring Purity and Durability

Test Design and Rationale

SANXIN’s Results

SANXIN’s Manufacturing Innovation

Raw Material Selection

Precision Forming and Sintering

Microstructure and Surface Engineering

Industry Applications and Case Studies

Lithium Battery Materials

Ceramics and Electronics

Coatings, Inks, and Pigments

Pharmaceuticals and Biotech

Comparative Analysis: SANXIN vs. Industry Standards

Customer Testimonials and Field Data

Future Directions and R&D

Conclusion

Contact Information

In the world of advanced materials, the quest for smaller, purer, and more uniform particles is relentless. Whether it’s to enhance the energy density of batteries, improve the clarity of electronic displays, or ensure the bioavailability of pharmaceuticals, the ability to control particle size at the submicron and nanometer scale is a foundational capability.

Wet ultrafine grinding—using bead mills charged with high-performance ceramic beads—has emerged as the technology of choice for producing these materials. Yet, as the demand for finer powders grows, so too does the challenge of developing grinding media that can deliver the necessary performance without compromising purity, durability, or process efficiency.

SANXIN’s breakthrough in manufacturing and validating 0.03mm zirconia beads represents a leap forward, not only in bead technology but in the entire ecosystem of wet ultrafine grinding.

Wet ultrafine grinding is a process in which solid particles are reduced in size by mechanical forces while suspended in a liquid medium, typically water or an organic solvent. The process is carried out in bead mills, where high-speed agitation causes grinding beads to collide with each other and with the suspended particles, breaking them down into finer and finer fragments.

Key mechanisms include:

Shear Forces: Generated as beads move past each other at high speed, shearing off material from larger particles.

Impact Forces: Resulting from direct collisions between beads and particles, causing fracture and size reduction.

Attrition: Gradual wearing down of particles as they are trapped between moving beads.

The size of the grinding media is a critical parameter:

Smaller beads provide a greater number of contact points, increasing the frequency and intensity of collisions.

Higher energy density is delivered to the particles, enabling more efficient size reduction.

Finer particle sizes (lower D50 values) are achievable, with improved dispersion and uniformity.

However, as bead size decreases, the demands on bead quality, mill design, and process control increase exponentially.

Zirconia (ZrO₂), especially when stabilized with yttria (Y₂O₃), is the material of choice for ultrafine grinding beads due to:

High density: Delivers more kinetic energy per collision.

Exceptional wear resistance: Minimizes contamination and extends bead life.

Chemical inertness: Maintains purity, even in aggressive environments.

Mechanical strength: Withstands the intense forces of high-speed milling.

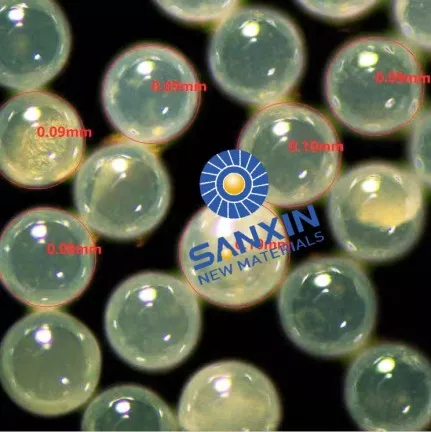

Manufacturing zirconia beads below 0.1mm presents unique challenges:

Uniformity: Ensuring tight size distribution to avoid segregation and uneven grinding.

Microstructure: Achieving a dense, flaw-free internal structure to prevent fracture.

Surface finish: Minimizing roughness to reduce friction and wear.

Separation: Designing bead mills capable of retaining such small beads without clogging or loss.

The transition from 0.1mm to 0.03mm beads is not a mere incremental improvement—it represents a step change in grinding dynamics:

Exponentially more contact points: For the same volume, 0.03mm beads provide over 30 times more beads than 0.1mm, vastly increasing the frequency of particle-bead interactions.

Higher energy transfer: More collisions at higher speeds lead to faster and more uniform size reduction.

Superior dispersion: Smaller beads can break up agglomerates more effectively, ensuring a stable, homogeneous slurry.

Enabling new products: Materials that were previously impossible to grind to the required fineness can now be produced.

Process efficiency: Faster grinding times, lower energy consumption, and reduced waste.

Quality assurance: Lower risk of contamination, more consistent product quality, and easier scale-up from lab to production.

The water milling test is a rigorous assessment of bead quality, simulating extended wet grinding under controlled conditions. It is designed to evaluate:

Wear resistance: How much material is lost from the beads over time.

Chemical stability: Whether the beads react with water or release contaminants.

Turbidity: Visual and quantitative measure of water clarity, indicating bead integrity.

Longevity: The ability of the beads to maintain performance over long durations.

SANXIN’s 0.03mm, 0.05mm, 0.1mm, and 0.3mm beads underwent the following tests:

Lab bead mill, 2300 rpm, 15 hours: Water remained clear with no visible discoloration or turbidity.

High-speed shaking, 24 hours: No turbidity observed, even with the smallest beads.

These results confirm:

Minimal wear: Beads maintain size and shape.

No contamination: Water purity is preserved, critical for sensitive applications.

Stable performance: Beads can be used for extended runs without degradation.

High-purity yttria-stabilized zirconia: Sourced from leading suppliers, ensuring minimal impurities and consistent composition.

Strict quality control: Every batch is analyzed for chemical and physical properties before use.

Advanced granulation techniques: Achieve uniform bead size and shape.

Controlled sintering: Optimized temperature and atmosphere profiles produce a dense, crack-free microstructure.

Post-sintering finishing: Polishing and sorting to ensure ultra-smooth surfaces and tight size distribution.

Dense internal structure: Eliminates pores and weak points, maximizing mechanical strength.

Smooth surface finish: Reduces friction, lowers wear, and improves grinding efficiency.

Ultra-narrow size distribution: Ensures consistent performance and prevents segregation in the mill.

Cathode and anode materials: LFP, NCM, solid electrolytes require submicron and nano-scale powders for optimal performance.

SANXIN beads: Enable the production of highly uniform, high-purity battery materials with improved energy density and cycle life.

Advanced ceramics: Used in electronic substrates, capacitors, and insulators demand ultra-fine, contamination-free powders.

SANXIN beads: Deliver the required fineness and purity, supporting next-generation electronic devices.

Nano pigments: For high-definition printing, automotive coatings, and display technologies.

Electronic inks: Require stable dispersions of conductive nanoparticles.

SANXIN beads: Achieve superior dispersion, color strength, and stability.

Active pharmaceutical ingredients (APIs): Particle size reduction enhances solubility and bioavailability.

SANXIN beads: Allow for gentle, contamination-free grinding suitable for sensitive biological compounds.

| Feature | SANXIN 0.03mm Beads | Typical Industry Beads (0.1mm+) |

|---|---|---|

| Minimum size | 0.03mm | 0.1mm |

| Wear resistance | Exceptional | Good to moderate |

| Chemical stability | High | Variable |

| Size distribution | Ultra-narrow | Moderate |

| Water milling test | Pass (clear, no turbidity) | Often fail at <0.1mm |

| Application range | Broad, incl. nanomaterials | Limited by minimum bead size |

"Switching to SANXIN’s 0.05mm beads allowed us to reduce our cathode material D50 by 30%, with no increase in contamination. The consistency from batch to batch is unmatched."

"The stability of our dispersions has improved dramatically. SANXIN beads are the only ones that passed our 24-hour water milling test without visible wear or color change."

Before: Conventional 0.1mm beads, D50 = 320 nm, processing time 12 hours

After: SANXIN 0.05mm beads, D50 = 220 nm, processing time 7 hours, no detectable zirconia in final product

SANXIN continues to invest in research and development to push the boundaries of wet ultrafine grinding:

Even smaller beads: Exploring the feasibility of 0.02mm and below.

Hybrid materials: Combining zirconia with other ceramics for tailored properties.

Smart beads: Embedding sensors for real-time monitoring of grinding conditions.

Sustainable manufacturing: Reducing energy and resource consumption in bead production.

Collaboration with academic and industrial partners ensures that SANXIN remains at the forefront of innovation.

The ability to reliably produce and deploy 0.03mm zirconia beads for wet ultrafine grinding is more than a technical achievement—it is a catalyst for innovation across multiple industries. SANXIN’s breakthrough addresses the twin challenges of performance and purity, enabling the next generation of high-tech materials and products.

Whether you are developing advanced batteries, cutting-edge ceramics, high-definition inks, or life-saving pharmaceuticals, SANXIN’s microbeads offer a proven solution for achieving the finest, purest, and most consistent results.

Ready to elevate your wet grinding process?

Contact SANXIN today to discuss your application and request a sample of our industry-leading 0.03mm zirconia beads.

Email: sales@beadszirconia.com

Website: www.beadszirconia.com

WhatsApp/Phone: +86-19070858212

A: SANXIN can accommodate both pilot-scale and full production orders. Please contact our sales team for details.

A: Our beads are compatible with most modern horizontal and vertical bead mills. For optimal performance, consult with our technical team regarding mill settings and separation systems.

A: While our beads represent a premium product, the total cost of ownership is often lower due to reduced wear, higher efficiency, and improved product quality.

A: Absolutely. Our technical experts can assist with process design, mill configuration, and troubleshooting to ensure maximum benefit from our beads.

Zhang, Y., et al. "Advances in Wet Ultrafine Grinding Technology." Journal of Materials Processing, 2023.

Smith, J. "The Role of Zirconia Beads in Nanomaterial Synthesis." Advanced Ceramics Review, 2024.

SANXIN Internal Test Reports, 2025.

SANXIN: Advancing the Science of Ultrafine Grinding.

Unlock the power of 0.03mm zirconia—contact us today!

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder