Nanotechnology is revolutionizing industries from energy storage to electronics, pharmaceuticals to advanced ceramics. Yet, behind every breakthrough in nanomaterials lies a critical, often underappreciated process: ultra-fine grinding. Horizontal bead mills, equipped with high-performance ceramic media, have become the backbone of industrial-scale nanomaterial production. This white paper explores the science, technology, and industrial impact of ultra-fine grinding with horizontal bead mills, with a focus on the role of SANXIN’s zirconia media in enabling reliable, scalable, and contamination-free nano-processing.

Introduction: Nanomaterials and the Need for Ultra-Fine Grinding

The Science of Nanoparticle Production

2.1 Bottom-Up vs. Top-Down Approaches

2.2 Why Top-Down Wet Milling Dominates Industry

Horizontal Bead Mills: Design, Operation, and Advantages

3.1 Key Components and Process Flow

3.2 Energy Efficiency and Scalability

3.3 Contamination Control

The Heart of the Process: High-Performance Grinding Media

4.1 Yttria-Stabilized Zirconia Beads

4.2 Size, Density, and Wear Resistance

4.3 Media Selection for Nanomaterial Applications

Process Parameters and Optimization

5.1 Rotor Speed and Shear Forces

5.2 Viscosity, Solid Loading, and Temperature Control

5.3 Dynamic Separation Systems

5.4 Achieving Sub-100 nm Particle Sizes

Application Fields

6.1 Advanced Ceramics and Electronics

6.2 Energy: Lithium Battery Materials

6.3 Mining and Metallurgy

6.4 Functional Coatings and Pigments

6.5 Catalysts and Pharmaceuticals

Industrial Trends and Future Outlook

7.1 Large-Scale, High-Throughput Systems

7.2 Smart Process Integration and Automation

7.3 Modular Support Systems

7.4 Tailored Ceramic Media

SANXIN: Solutions and Support for Nano-Grinding

8.1 Custom Media Engineering

8.2 Technical Service and Process Consulting

8.3 Case Studies and Global Reach

Environmental, Economic, and Regulatory Impacts

Conclusion

Frequently Asked Questions

References

Contact Information

The 21st century is the age of nanotechnology. From the batteries powering electric vehicles to the semiconductors in smartphones, the demand for materials engineered at the nanometer scale is accelerating. Nanomaterials offer unique properties—higher surface area, improved reactivity, enhanced strength, and novel optical or electronic behaviors—that are simply unattainable in bulk or micron-sized materials.

However, producing these nanomaterials at industrial scale is a formidable challenge. While chemical synthesis (“bottom-up” methods) can create nanoparticles, these approaches are often expensive, difficult to scale, and yield broad particle size distributions. For most high-value industrial applications, top-down wet milling using horizontal bead mills remains the dominant technology for producing high-purity, uniform nano powders efficiently and cost-effectively.

Definition: Building nanoparticles atom-by-atom or molecule-by-molecule.

Examples: Sol-gel processing, vapor deposition, precipitation, and chemical synthesis.

Advantages: Can produce very small, uniform particles; suitable for some specialty applications.

Limitations: High cost, complex process control, difficulty in scaling up, impurities, and broad particle size distributions.

Definition: Mechanical size reduction of larger particles, usually via wet milling.

Examples: Ball milling, jet milling, and, most efficiently, horizontal bead milling.

Advantages: High throughput, scalability, lower cost, and easier process control.

Horizontal bead mills are the most effective top-down equipment for producing nano powders at industrial scale.

Scalability: Easily scaled from laboratory to production volumes.

Consistency: Narrow particle size distributions and repeatable results.

Purity: Minimal contamination when using high-quality ceramic media.

Versatility: Suitable for a wide range of materials, including hard ceramics, metals, minerals, and organics.

Cost-Effectiveness: Lower capital and operational costs compared to many bottom-up methods.

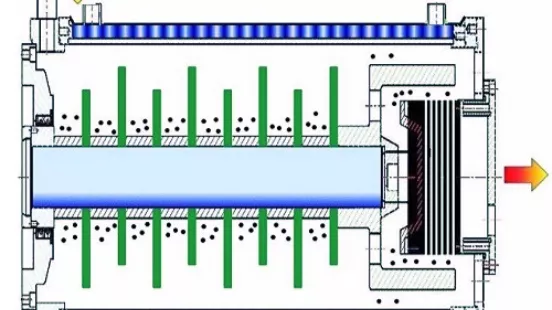

A horizontal bead mill consists of:

Grinding Chamber: Filled with grinding media (usually ceramic beads).

Rotor/Stator System: Provides high-speed agitation, creating intense shear and impact forces.

Separation System: Retains beads while allowing processed slurry to exit.

Cooling System: Maintains temperature control to prevent material degradation.

Process Flow:

Feed slurry enters the chamber, is rapidly agitated by the rotor, and subjected to collisions with the beads. The resulting mechanical forces break down particles to submicron or nanometer sizes. The processed slurry is then separated from the beads and collected.

Energy Input: Linear rotor speeds often exceed 16 m/s, delivering high energy density for efficient size reduction.

Scalability: Horizontal mills are available in lab, pilot, and large industrial sizes, with capacities from a few liters to thousands of liters.

Continuous Operation: Many mills are designed for 24/7 operation, supporting high-throughput industrial demands.

Material Selection: All wetted parts can be made from ceramics or high-grade alloys to minimize contamination.

Media Quality: High-purity yttria-stabilized zirconia beads are preferred for their inertness and wear resistance.

Process Sealing: Advanced sealing systems prevent ingress of contaminants and loss of product.

Yttria-stabilized zirconia (YSZ) beads are the gold standard for nano-grinding due to:

High density (~6.0 g/cm³): Delivers more kinetic energy per collision.

Hardness (Mohs 9): Enables grinding of hard and abrasive materials.

Chemical Inertness: Prevents contamination of sensitive products.

Wear Resistance: Extends bead and mill life, reducing operating costs.

Bead Size: For nano-grinding, beads typically range from 0.1 to 1.8 mm. Smaller beads provide more contact points and finer grinding, but require advanced separation systems.

Density: High-density beads transfer more energy, improving grinding efficiency.

Wear Resistance: Superior microstructure and surface finish minimize bead degradation and product contamination.

Material Compatibility: YSZ beads are suitable for ceramics, minerals, battery materials, pigments, pharmaceuticals, and more.

Customization: Beads can be tailored for size, density, and surface properties to match specific process requirements.

Specialty Media: Magnetic beads, hybrid ceramics, and application-specific formulations are available for unique needs.

High linear speeds (>16 m/s): Generate intense shear and impact, critical for breaking down agglomerates and primary particles.

Adjustable RPM: Allows tuning for different materials and target particle sizes.

Energy Transfer: The energy imparted by the rotor is transferred to the beads, which then impact and shear the particles in the slurry.

Slurry Viscosity: Optimal viscosity (<1000 cps) ensures efficient energy transfer and uniform grinding.

Solid Loading: High solid content (<65%) increases throughput but must be balanced to avoid excessive viscosity.

Temperature Management: Maintaining temperatures below 90°C prevents material degradation and maintains slurry stability.

Cooling Systems: Advanced cooling jackets and temperature sensors ensure process stability.

Screen Gap: Advanced dynamic separation systems with screen gaps as fine as 0.8 mm retain small beads while allowing product flow.

Prevents Bead Loss: Ensures process stability and cost efficiency.

Separation Efficiency: Critical for high-value or high-purity applications.

Process Optimization: A combination of bead size, rotor speed, viscosity, and temperature control enables reduction to sub-100 nm particle sizes, even for ultra-hard or high-purity materials.

Process Monitoring: Real-time particle size analysis and feedback control optimize results.

Materials: Alumina, silicon carbide, zirconia, dielectric materials.

Applications: Electronic substrates, capacitors, high-strength ceramics.

Requirements: Ultra-fine, uniform particles for sintering and performance.

Case Study: SANXIN’s zirconia beads have enabled the production of sub-100 nm alumina powders for next-generation MLCC (multi-layer ceramic capacitor) manufacturing, resulting in higher capacitance and reliability.

Materials: LFP, NCM, solid electrolytes, conductive carbons.

Applications: Cathode and anode materials for lithium-ion and solid-state batteries.

Requirements: High purity, narrow particle size distribution, minimal contamination.

Case Study: SANXIN media are used by leading battery manufacturers to produce high-performance LFP cathode powders, improving energy density and cycle life.

Materials: Iron ore, copper, gold, non-metallic minerals.

Applications: Regrinding for mineral liberation, flotation, and concentrate preparation.

Requirements: Efficient grinding to 400 mesh or finer, high throughput.

Case Study: In gold ore processing, SANXIN’s high-density beads have reduced energy consumption and improved gold recovery rates by achieving finer liberation.

Materials: TiO₂, ZnO, SiO₂, specialty pigments.

Applications: Paints, inks, coatings, high-performance pigments.

Requirements: Uniform dispersion, color strength, stability.

Case Study: SANXIN’s beads have enabled pigment manufacturers to achieve brighter, more stable colors with improved coverage and durability.

Materials: Precious metal catalysts, APIs, excipients.

Applications: Catalytic converters, drug formulations.

Requirements: Submicron particles, strict purity control, biocompatibility.

Case Study: Pharmaceutical companies have used SANXIN media to produce nano-API suspensions with improved solubility and bioavailability.

Industry Demand: “High volume, fine particle size, low energy consumption, and process stability.”

Trend: Adoption of large-capacity horizontal mills for continuous, high-throughput production.

Global Expansion: Emerging markets and established industries alike are investing in larger, more automated bead milling systems.

Digital Controls: Real-time monitoring and adjustment of process parameters.

Automation: Integration with upstream and downstream processes for seamless production.

Industry 4.0: IoT-enabled mills provide predictive maintenance and process optimization.

Flexibility: Modular designs allow easy scaling and adaptation to changing production needs.

Maintenance: Simplified maintenance and rapid changeover for different products.

Upgradability: Modular systems can be upgraded with new technology as it becomes available.

Customization: Media engineered for specific materials, target particle sizes, and process conditions.

Innovation: Ongoing R&D in bead composition, size, and surface engineering.

Sustainability: Development of recyclable and environmentally friendly media.

Yttria-Stabilized Zirconia Beads: Available in a range of sizes (0.03 mm to 1.8 mm), densities, and surface finishes.

Specialty Media: Magnetic beads, hybrid ceramics, and application-specific formulations.

Quality Control: Each batch is rigorously tested for size distribution, density, hardness, and purity.

Lab Testing: Support for process development and optimization.

Scale-Up Assistance: From pilot to full production, SANXIN helps customers achieve reliable, scalable results.

Troubleshooting: On-site and remote support for process challenges.

Training: Operator training and best practices for optimal mill performance.

Battery Materials: SANXIN media used by leading battery manufacturers for LFP and NCM production.

Ceramic Electronics: Supplying high-purity beads for advanced ceramic and electronic applications.

Mining: Proven performance in mineral regrinding and concentrate preparation.

Global Network: SANXIN supports customers in over 50 countries, providing technical expertise and rapid logistics.

Reduced Waste: Longer-lasting media and efficient grinding processes minimize waste generation.

Lower Energy Consumption: High-efficiency mills and media reduce overall energy usage.

Water Recycling: Closed-loop systems and advanced filtration minimize water consumption.

Lower Total Cost of Ownership: Durable media and efficient mills reduce operational costs.

Increased Yield: Finer, more uniform particles improve product performance and value.

Faster Time to Market: Scalable, reliable processes accelerate product development.

Purity Standards: SANXIN media meet stringent purity requirements for pharmaceutical and electronic applications.

Safety: Mills and media are designed to comply with global safety standards.

Documentation: Full traceability and certification for quality assurance.

Ultra-fine grinding with horizontal bead mills is the engine driving the nanotechnology revolution. By combining advanced mill design, optimized process parameters, and high-performance ceramic media, industries can reliably produce high-purity nanomaterials at scale. SANXIN’s expertise in zirconia media and technical support ensures customers can meet the demands of tomorrow’s advanced materials—efficiently, consistently, and with confidence.

Q1: What is the smallest particle size achievable with horizontal bead mills?

A: With optimized parameters and high-quality media, sub-100 nm particle sizes are routinely achieved for many materials.

Q2: How do I select the right bead size and type for my application?

A: Consider your target particle size, material hardness, and process requirements. SANXIN’s technical team can recommend the optimal media.

Q3: What are the main causes of contamination in nano-grinding, and how can they be avoided?

A: Contamination can arise from bead wear, mill components, or process fluids. Using high-purity yttria-stabilized zirconia beads and ceramic-lined mills minimizes this risk.

Q4: Can horizontal bead mills be used for both wet and dry grinding?

A: They are primarily designed for wet grinding, which enables finer particle sizes and better dispersion.

Q5: How does SANXIN support customers scaling up from lab to industrial production?

A: SANXIN offers lab-scale testing, process optimization, and technical support throughout the scale-up process.

Q6: What is the typical lifespan of SANXIN zirconia beads?

A: Lifespan depends on process parameters and materials, but SANXIN beads are engineered for maximum durability and minimal wear.

Q7: Are SANXIN beads suitable for food or pharmaceutical applications?

A: Yes, SANXIN offers high-purity grades with full certification for sensitive applications.

Advances in Wet Ultrafine Grinding Technology, Journal of Materials Processing, 2023.

The Role of Zirconia Beads in Nanomaterial Synthesis, Advanced Ceramics Review, 2024.

SANXIN Internal Application Reports, 2025.

Industry Standards for Nanomaterial Production, ISO/TC 229, 2022.

Battery Materials and Nanotechnology, Energy Storage Journal, 2024.

Ready to scale up your nano grinding process?

Contact SANXIN for technical support, custom media solutions, or to request a quote.

Email: sales@beadszirconia.com

Website: www.beadszirconia.com

Phone/WhatsApp: +86-19070858212

SANXIN: Empowering the Future of Nanomaterials with Precision Grinding Solutions.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder