In industries ranging from metallurgy and mining to building materials and food processing, fine-grained material grinding is a critical step in production. Whether it’s reducing ore to micrometer-sized particles for mineral processing, refining ceramics into powders for advanced materials, or pulverizing food additives for uniform mixing, the efficiency and reliability of grinding equipment directly impact product quality, operational costs, and overall profitability. Among the most widely used machines for this task is the stirred ball mill—a high-performance device designed to achieve ultra-fine grinding through intense agitation of grinding media. However, while stirred ball mills excel at efficiency, their high-speed, high-intensity operation creates extreme wear conditions that have long plagued operators.

This article explores how wear-resistant ceramic lining solutions are transforming stirred ball mill performance, addressing the industry’s most pressing challenges of frequent maintenance, high costs, and production downtime. We’ll dive into the science behind these ceramic liners, their design innovations, material selection, and real-world applications—proving why they’re becoming the gold standard for fine-grained grinding operations.

Stirred ball mills have revolutionized fine grinding by overcoming the limitations of traditional ball mills. Unlike conventional mills, which rely on rotational motion to tumble grinding media, stirred ball mills use a central agitator (typically a rotating shaft with impellers or discs) to vigorously stir a dense mixture of grinding media (balls or beads) and material. This agitation creates intense impact, shear, and friction forces, allowing for finer particle size reduction—often down to the sub-micron range—with shorter processing times.

Their popularity stems from several key advantages:

Higher efficiency: Stirred ball mills achieve finer grind sizes (often <10 μm) with lower energy consumption per unit of product compared to traditional mills.

Compact design: They occupy less floor space, making them ideal for plants with limited room.

Precise control: Operators can adjust agitator speed, media size, and fill ratio to tailor grinding to specific material requirements.

These benefits have made stirred ball mills indispensable in:

Mining and metallurgy: Grinding ore concentrates (e.g., copper, gold, lithium) to liberate valuable minerals for extraction.

Ceramics and advanced materials: Producing ultra-fine ceramic powders for electronics, aerospace components, and refractory materials.

Food and pharmaceuticals: Reducing particle sizes in additives, supplements, and active pharmaceutical ingredients (APIs) for better solubility and uniformity.

Waste recycling: Processing slag, fly ash, and other industrial byproducts into reusable materials.

While stirred ball mills offer unmatched grinding efficiency, their design comes with a significant tradeoff: extreme wear on internal components. The same high-speed agitation that enables fine grinding subjects the mill’s inner lining (the cylinder wall in contact with media and material) to relentless punishment. Over time, this wear leads to frequent liner replacements, unplanned downtime, and increased operational costs—undermining the mill’s efficiency gains.

To understand the problem, let’s break down the three primary types of wear affecting stirred ball mill liners:

In a stirred ball mill, the agitator rotates at speeds ranging from 500 to 2,000 RPM, depending on the application. This motion propels grinding media (typically steel, ceramic, or glass balls/beads) against the cylinder wall with tremendous force. For example, a 5mm diameter grinding ball moving at 1,000 RPM can strike the liner thousands of times per minute.

Traditional metal liners—often made of manganese steel or high-chrome alloys—absorb these impacts but deform over time. The repeated stress causes micro-cracks, dents, and eventual thinning of the liner surface. In severe cases, this can lead to holes in the liner, allowing abrasive material to leak and damage the mill’s outer shell.

A mining operation in Chile, for instance, reported that the metal liner in its 500L stirred ball mill (used for grinding copper concentrate) developed visible wear after just 200 hours of operation. By 500 hours, the liner was so thin that it required emergency replacement to prevent equipment failure.

Many materials processed in stirred ball mills—such as quartz-rich ores, alumina ceramics, or silica-based minerals—are inherently abrasive. Even at fine sizes (1–100 μm), these particles act like sandpaper, scouring the liner surface as they’re pushed against it by the agitated media. Abrasive wear is especially problematic because it speeds up the breakdown of metal liners. Manganese steel, for example, has a hardness of 50–55 HRC (Rockwell C), which is not enough to resist materials like quartz (Mohs hardness 7) or alumina (Mohs hardness 9). Over time, the liner surface becomes rough and uneven, increasing friction, lowering grinding efficiency, and creating pockets where material can build up (known as “hanging material”). In a case study from a Chinese ceramics plant, a stirred ball mill processing alumina powder (95% Al₂O₃) required liner replacement every 30 days because of abrasive wear. Each replacement took 8 hours, stopping production and costing about $5,000 in labor and lost output.

In many industries, the material being ground is mixed with water or chemicals to form a slurry. For example, mining operations often use acidic or alkaline solutions to aid in mineral liberation, while pharmaceutical plants may use organic solvents to dissolve active ingredients. These slurries can chemically attack metal liners, leading to corrosive wear.

Corrosion weakens the liner’s structure, making it more susceptible to impact and abrasive wear. In extreme cases, it can cause pitting—small holes that grow larger as the liner thins. A European zinc smelter, for instance, struggled with liners in its stirred ball mills that corroded rapidly due to the acidic zinc sulfate slurry. The liners lasted just 45 days, despite being made of “corrosion-resistant” stainless steel.

The combination of impact, abrasive, and corrosive wear creates a “wear cycle” that plagues stirred ball mill operators:

Liner wear reduces grinding efficiency (rough surfaces increase friction, hanging material reduces effective volume).

Frequent replacements (often every 30–90 days) cause unplanned downtime, disrupting production schedules.

High costs: Replacement liners, labor, and lost output add up—often totaling hundreds of thousands of dollars annually for a single mill.

Worse, traditional “solutions” to extend liner life—such as increasing liner thickness or using higher-alloy metals—only compound the problem. Thicker liners add weight, increasing energy consumption. High-alloy metals (e.g., nickel-chromium alloys) are 3–5 times more expensive than standard steel, driving up upfront costs without addressing the root cause of wear.

For decades, the industry accepted frequent liner replacements as an unavoidable cost of doing business. That changed with the development of wear-resistant ceramic liners—engineered specifically to withstand the harsh conditions of stirred ball mills.

Unlike metal, ceramics combine extreme hardness, chemical inertness, and tailored toughness to resist impact, abrasion, and corrosion. SANXIN’s specialized ceramic lining solutions for stirred ball mills build on this material advantage with innovative designs, creating a system that outperforms metal liners by every metric.

The success of ceramic liners stems from their unique material properties, honed through advanced manufacturing techniques. SANXIN offers two high-performance ceramic options, each optimized for specific wear conditions:

Alumina ceramics are composed primarily of aluminum oxide (Al₂O₃), a naturally hard material. By increasing the purity of Al₂O₃ (from 92% to 99%), manufacturers enhance its hardness and wear resistance:

Hardness: 85–90 HRA (Rockwell A), compared to 50–55 HRC for manganese steel. This makes alumina 2–3 times more resistant to abrasive wear.

Abrasion resistance: In lab tests, 95% alumina ceramic liners showed 1/10th the wear rate of manganese steel when exposed to quartz slurry.

Corrosion resistance: Alumina is chemically inert, unaffected by acids, alkalis, or organic solvents—eliminating corrosive wear.

High-purity alumina ceramics excel in low-to-moderate impact environments, such as fine grinding of non-abrasive to moderately abrasive materials (e.g., limestone, talc, or pharmaceutical powders).

For high-impact conditions—such as grinding with large media (10–20mm diameter) or processing ultra-hard materials—SANXIN developed ZTA ceramics. These are alumina ceramics reinforced with zirconia (ZrO₂) nanoparticles, a technology that solves ceramics’ historic weakness: brittleness.

Zirconia particles act as “micro-crack absorbers.” When an impact occurs, tiny cracks form around the zirconia particles, dissipating energy instead of spreading and causing the ceramic to shatter. The result is a material with:

Hardness: 90–92 HRA (even higher than high-purity alumina).

Toughness: 3–4 times greater than standard alumina, measured by fracture toughness (4–6 MPa·m¹/² vs. 2–3 MPa·m¹/² for pure alumina).

Impact resistance: ZTA liners withstand repeated strikes from 10mm steel balls at 1,500 RPM without cracking—performance unheard of in traditional ceramics.

ZTA ceramics are ideal for high-impact, high-abrasion applications, such as grinding ore concentrates, slag, or silicon carbide.

Material performance alone isn’t enough—ceramic liners must be engineered to withstand the unique dynamics of stirred ball mills. SANXIN’s solutions incorporate three key design innovations:

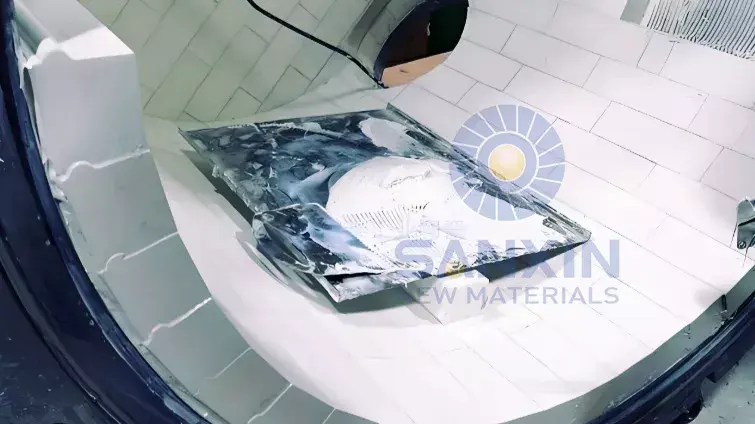

Stirred ball mills have irregular, often curved internal surfaces, making custom-fitted liners a necessity. SANXIN’s modular design uses standard-sized ceramic bricks (typically 50mm thick, with dimensions ranging from 100×100mm to 200×300mm) that can be arranged to fit any mill geometry.

Precision cutting: Bricks are CNC-machined to ensure tight, gap-free joints, preventing material from seeping behind the liner and causing damage.

Interlocking edges: Many bricks feature tongue-and-groove designs to resist lateral movement during agitation.

Scalable replacement: Instead of replacing the entire liner when wear occurs, operators can swap out individual bricks—reducing downtime and material costs.

A U.S. mineral processing plant reported that replacing a single worn brick in its stirred ball mill took just 30 minutes, compared to 8 hours for a full metal liner replacement.

Stirred ball mills generate intense vibration and centrifugal force, which can dislodge poorly secured liners. SANXIN uses a multi-layer fixing system to ensure ceramics stay in place:

High-temperature epoxy adhesive: Bonds the ceramic to the mill’s metal shell, creating a strong initial seal.

Mechanical self-locking fasteners: Stainless steel bolts or clips anchor bricks to the shell, preventing movement under vibration.

Stud welding: For high-impact zones (e.g., near the agitator), metal studs are welded to the shell, and bricks are drilled to fit over them—adding an extra layer of security.

In field tests, this system withstood 2,000 RPM agitation for 1,000 hours with no liner displacement—a critical advantage over early ceramic liners, which often fell out under stress.

Even the hardest liners can suffer from “hanging material”—the accumulation of slurry or particles on the surface, which reduces grinding efficiency and increases wear. SANXIN addresses this with specialized surface treatments:

Polished finishes: A smooth, mirror-like surface (Ra < 0.8 μm) reduces friction, allowing material to slide off instead of sticking.

Glaze coatings: For high-moisture applications, a thin ceramic glaze is applied to further repel water-based slurries.

In a food processing plant grinding wheat flour, this surface optimization reduced hanging material by 90%, cutting cleaning time from 2 hours per week to 15 minutes.

The true value of ceramic liners lies in their ability to transform stirred ball mill economics. By addressing wear at its source, they deliver measurable improvements in cost, efficiency, and reliability:

In real-world applications, ceramic liners outlast metal by a factor of 3 to 10. For example:

A gold mine in Australia replaced metal liners in its stirred ball mill (used for regrinding flotation concentrates) with 95% alumina ceramics. Liner life increased from 60 days to 540 days—a 9x improvement.

A Chinese zirconia powder plant using ZTA liners in its high-speed stirred mill saw liner life jump from 45 days to 360 days—8x longer than metal.

This extended lifespan eliminates the “replacement cycle,” freeing up maintenance teams for other tasks and ensuring uninterrupted production.

Fewer replacements mean lower spending on labor, materials, and downtime. A mid-sized mining operation with three stirred ball mills reported:

Before ceramics: $40,000 per year per mill in liner replacements, labor, and lost output.

After ceramics: $8,000 per year per mill—an 80% reduction.

Over five years, this translates to $480,000 in savings for the three mills.

The smooth surface of ceramic liners reduces friction between the grinding media and the liner wall. This lowers the agitator’s power draw, cutting energy consumption. A European ceramics plant measured a 12% reduction in electricity use after switching to SANXIN’s ceramic liners—saving $15,000 annually per mill.

Metal liners can contaminate the material being ground with wear particles (e.g., iron from steel liners), which is problematic for high-purity applications. Ceramic liners are inert: alumina and zirconia do not react with materials, ensuring product purity.

A lithium battery material plant, for instance, switched to ceramic liners to avoid iron contamination in its lithium carbonate grinding process. This reduced impurity levels from 0.05% to <0.001%, making the product eligible for high-value battery-grade markets.

Not all stirred ball mills face the same wear conditions. To maximize performance, SANXIN recommends selecting ceramics based on three key factors: material abrasiveness, impact intensity, and slurry chemistry.

Best for: Low-to-moderate impact, abrasive wear-dominated environments.

Ideal applications:

Fine grinding of limestone, talc, or clay (building materials).

Food processing (e.g., grinding spices, starches).

Pharmaceutical APIs (where purity is critical).

Non-abrasive mineral slurries (e.g., some rare earth ores).

Why choose: Cost-effective, excellent abrasion resistance, and chemical inertness. 99% alumina is recommended for the highest purity requirements.

Best for: High-impact, high-abrasion conditions.

Ideal applications:

Grinding ore concentrates (copper, gold, nickel) with large media (10–20mm).

Processing ultra-hard materials (silica, silicon carbide, zirconia).

Slurries with high solid content (increasing impact forces).

Why choose: Superior toughness and impact resistance, ensuring longevity in harsh environments.

To avoid damaging ceramic liners, it’s critical to use ceramic grinding media (e.g., zirconia beads, alumina balls) instead of steel media. Steel balls are harder than metal liners but softer than ceramic liners—using them would cause rapid wear to the ceramic surface. Ceramic media, by contrast, have similar hardness to the liners, reducing mutual wear and extending both media and liner life.

To illustrate the real-world impact of ceramic liners, let’s examine a case study from a copper mine in Peru. The mine operates four 1,000L stirred ball mills for regrinding flotation concentrates, a step critical to liberating fine copper particles for recovery.

The mine struggled with:

Metal liners lasting just 45 days due to abrasive wear from quartz-rich ore.

Monthly shutdowns (8 hours each) for liner replacements, costing $25,000 per shutdown in lost production.

Iron contamination from worn steel liners, reducing copper concentrate purity and lowering sale prices.

SANXIN recommended ZTA ceramic liners (50mm thick) paired with 10mm zirconia grinding media. The liners were installed using a combination of epoxy adhesive and mechanical fasteners to withstand high agitation speeds (1,200 RPM).

Liner life: Increased from 45 days to 405 days—a 9x improvement.

Downtime: Reduced from 12 shutdowns per year to 1.5, saving $287,500 annually in lost output.

Contamination: Iron levels in the concentrate dropped from 0.3% to 0.02%, allowing the mine to sell at a 5% premium.

Energy use: Decreased by 8%, saving $9,000 per mill annually.

Over three years, the mine calculated a total return on investment (ROI) of 320% from the ceramic liner upgrade.

Stirred ball mills are indispensable for fine-grained grinding, but their efficiency has long been undermined by excessive wear. Traditional metal liners offer temporary solutions at best, creating a cycle of replacement, downtime, and rising costs.

Wear-resistant ceramic liners—with their unmatched hardness, toughness, and chemical inertness—break this cycle. By extending liner life 3–10x, slashing maintenance costs, and improving energy efficiency, they deliver tangible value to operations across industries. Whether processing ores, ceramics, food, or pharmaceuticals, ceramic liners are proven to reduce costs and boost efficiency.

At SANXIN, we don’t just supply liners—we partner with operators to design custom solutions tailored to their unique grinding conditions. From material selection and 3D modeling to installation and ongoing support, our team ensures seamless integration and maximum performance.

Ready to transform your stirred ball mill operations? Contact us today to schedule a wear assessment and discover how ceramic liners can reduce costs and boost efficiency in your facility.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder