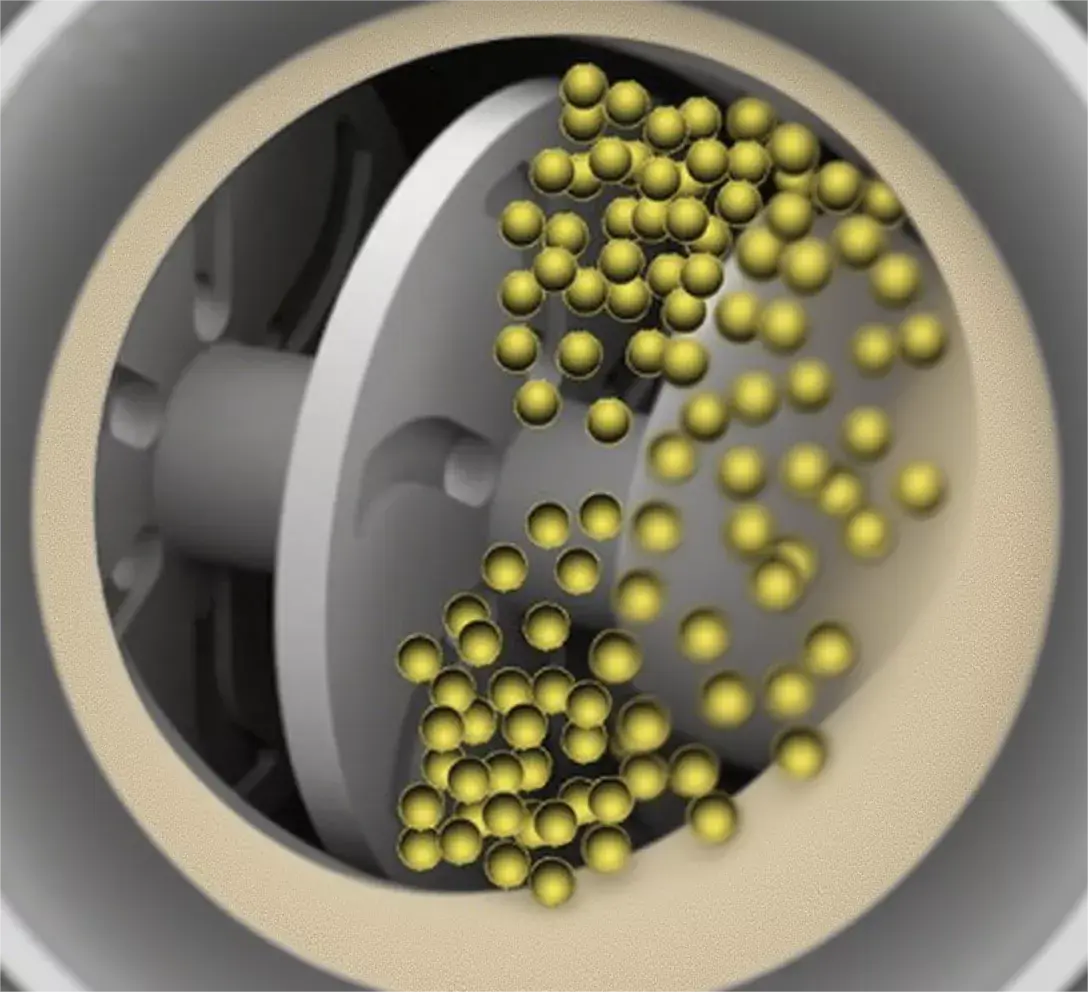

In the world of industrial processing—where pharmaceuticals, battery materials, paints, and food products demand ever-finer particle sizes—wet milling has become indispensable. This process transforms coarse raw materials into uniform, micron-scale powders, enabling better solubility in drugs, higher energy density in batteries, and smoother textures in cosmetics. Yet, for all its precision, wet milling relies on a surprisingly small but powerful component: grinding beads. These tiny spheres (ranging from 0.1mm to 20mm) are the workhorses of the milling chamber, driving particle size reduction, dispersion, and homogenization.

Far too often, grinding beads are treated as a commodity—selected based on cost rather than performance. But in reality, the beads in your milling chamber are a make-or-break factor for efficiency, product quality, and profitability. A poor choice can lead to extended batch times, inconsistent particle sizes, equipment damage, and costly rework. A strategic choice, by contrast, can cut production time by 30%, reduce energy use by 20%, and ensure compliance with strict industry standards.

In this expanded guide, we’ll explore why grinding bead selection matters, dive into the science behind common bead types, examine how bead properties directly impact your product, and explain how to partner with experts to find the perfect match for your process.

Grinding beads are not “one-size-fits-all.” Their size, material, density, and hardness interact with your product, equipment, and process parameters in ways that can either optimize performance or create costly bottlenecks. Let’s unpack the seven critical reasons why selecting the right beads is non-negotiable—with new insights and case studies to illustrate their impact:

At its core, wet milling is about reducing particles to a target size—whether 1μm for lithium-ion battery cathodes or 50μm for agricultural pesticides. The right grinding beads accelerate this process by maximizing contact with particles, ensuring every batch reaches the desired fineness quickly and uniformly.

How beads drive efficiency: Smaller beads (0.3–1mm) have a larger total surface area, allowing more frequent collisions with tiny particles. This is critical for nanoscale grinding, where even a 1μm difference in particle size can render a product unusable. For example, in lithium-ion battery production, cathode particles larger than 5μm reduce energy density and cycle life. Larger beads (5–20mm) excel at breaking down coarser agglomerates, using their mass to deliver high-impact force—ideal for grinding ore chunks into manageable fines.

The cost of poor selection: A battery material manufacturer learned this the hard way when producing nickel cobalt manganese (NCM) cathodes. They initially used 2mm zirconium silicate beads, but the beads were too large to efficiently reduce particles below 8μm. This forced them to extend milling time by 3 hours per batch, increasing energy use and causing unwanted particle agglomeration. Switching to 0.5mm yttria-stabilized zirconia (YTZ) beads cut milling time by 60% and achieved a consistent 3μm particle size, meeting automotive-grade specifications.

Uniformity is equally important. Inconsistent particle sizes (e.g., a mix of 1μm and 10μm particles in a paint formulation) lead to uneven color, poor coverage, or failed quality checks. Beads with consistent hardness and shape ensure that every particle in the batch is subjected to the same grinding intensity, eliminating “overs” (too large) and “unders” (too small).

Wet milling is an energy-intensive process, and grinding beads act as the bridge between the mill’s mechanical energy (from agitators or rotors) and the particles being ground. Their ability to transfer energy directly impacts how quickly and effectively you reduce particle size.

Key energy drivers:

Density: Heavier beads (e.g., zirconia, density ~6g/cm³) carry more kinetic energy, delivering harder impacts that break down tough particles faster. For example, a 5mm YTZ bead (density 6.2g/cm³) moving at 1,000 RPM transfers 2.5x more energy than a 5mm glass bead (density 2.5g/cm³) at the same speed. This makes zirconia beads ideal for grinding hard materials like alumina or silicon carbide.

Hardness: Harder beads (e.g., YTZ, hardness 9 Mohs) maintain their shape under high stress, ensuring consistent energy transfer. Soft beads (e.g., plastic, hardness 2–3 Mohs) deform on impact, wasting energy as heat rather than grinding force.

The risk of mismatch: A mineral processing plant tried to grind quartz (Mohs hardness 7) using 5mm glass beads (Mohs hardness 5). The beads were too soft and light to transfer enough energy—even after 8 hours of milling, 40% of particles remained above the target size. Switching to 5mm zirconium silicate beads (Mohs hardness 6.5, density 4.3g/cm³) reduced milling time to 2 hours, cutting energy use by 75% and lowering carbon emissions by 300 tons annually.

In industries like pharmaceuticals, cosmetics, and electronics, product quality is non-negotiable. Even minor inconsistencies can lead to failed regulatory audits, product recalls, or lost contracts. Grinding beads play a hidden but critical role in maintaining quality.

Dispersion vs. agglomeration: Many products (e.g., inks, coatings, battery slurries) require uniform dispersion of particles to perform. Beads with irregular shapes or uneven hardness can create “dead zones” in the milling chamber, where particles clump together (agglomerate) instead of dispersing. Spherical beads with consistent hardness ensure that shear forces are evenly distributed, breaking up clumps and keeping particles separated.

Fineness control: For products like sunscreen (where particle size affects UV protection) or catalyst powders (where surface area impacts reactivity), precise fineness is key. A cosmetics manufacturer, for example, switched from 1mm cerium-stabilized zirconia (ZrCe) beads to 0.5mm beads to reduce titanium dioxide particle size from 3μm to 1μm. This not only improved the sunscreen’s SPF rating by 20% but also made the texture smoother, reducing customer complaints by 40%.

Consistency across batches is equally vital. Beads that wear unevenly (e.g., low-quality glass beads that chip) introduce variability: one batch may grind to 2μm, the next to 5μm, due to changes in bead size or shape. High-quality beads with tight tolerances (e.g., YTZ beads with ±0.05mm size variation) ensure that every batch performs like the first—critical for meeting ISO 9001 or FDA standards.

Your milling equipment is a significant investment—often costing $50,000 to $500,000. The wrong grinding beads can shorten its lifespan, leading to expensive repairs or replacements.

Bead hardness vs. equipment wear: Beads harder than the mill’s chamber lining or agitator will abrade these components over time. For example, using YTZ beads (Mohs 9) in a mill with a stainless steel chamber (Mohs 5.5) will quickly scratch and thin the lining, requiring replacement every 6 months at a cost of $15,000 per replacement. Conversely, beads softer than the product (e.g., plastic beads grinding quartz) will break down, leaving fragments that jam the mill or damage seals—costing $10,000 in unplanned downtime.

Shape and smoothness: Irregularly shaped beads (e.g., crushed ceramic fragments) create friction as they move, increasing wear on agitator shafts and bearings. Spherical, polished beads (e.g., YTZ or glass) flow smoothly, reducing friction and extending equipment life. A paint manufacturer learned this lesson after using low-cost, irregularly shaped zirconium silicate beads: within 3 months, the mill’s agitator bearings wore out, costing $20,000 in repairs and 2 weeks of downtime. Switching to spherical zirconium silicate beads with a polished surface extended bearing life to 18 months.

Nothing derails a production run faster than contamination. Grinding beads can introduce impurities in two ways: chemical reactivity (e.g., beads dissolving in acidic slurries) or physical wear (e.g., metal beads shedding particles into the product).

Chemical compatibility: Beads must resist corrosion or dissolution in your product’s slurry. For example, aluminum-based beads will react with acidic pharmaceuticals, releasing aluminum ions that contaminate the API and fail USP testing. Zirconia beads (YTZ or ZrCe), by contrast, are chemically inert, withstanding acids (pH 1–2), alkalis (pH 12–13), and organic solvents like ethanol or acetone.

Wear-induced contamination: All beads wear over time, but the rate and type of wear matter. Steel beads, for example, shed iron oxide particles—ruining products like white paints or high-purity ceramics. Glass beads can leach silica, which is problematic for pharmaceutical injectables (silica levels must be <0.1mg/L per USP standards). YTZ beads, with their ultra-low wear rate (0.01% weight loss per 100 hours of milling), minimize contamination to levels below 1ppm—critical for industries like semiconductors (where even trace metals can disrupt chip performance) or parenteral drugs.

A lithium-ion battery plant faced a crisis when iron contamination from steel grinding beads caused battery cells to short-circuit during testing. Switching to YTZ beads eliminated iron impurities, allowing the plant to meet automotive-grade standards (ISO 16232) and secure a $10M contract with a major automaker.

In high-volume industries (e.g., paints, agrochemicals, minerals), throughput—the amount of product processed per hour—directly impacts profitability. The right grinding beads optimize flow rates, reduce clogging, and minimize “losses” (product trapped in the mill or wasted due to poor quality).

Flow dynamics: Beads that are too large can block inlet/outlet screens, slowing flow and forcing operators to stop the mill for cleaning. Beads that are too small can slip through screens, mixing with the product and requiring costly separation steps (e.g., centrifugation). A crop protection company solved a throughput bottleneck by switching from 0.3mm to 0.5mm glass beads: the larger beads didn’t clog screens, increasing hourly output by 40% and reducing labor costs for cleaning by $8,000/month.

Yield improvement: Poorly selected beads leave more product stuck to the mill walls or trapped in agglomerates, reducing yield. Smooth, non-stick beads (e.g., polished zirconia) minimize product buildup, ensuring more material exits the mill as usable product. A food processing plant producing protein powder increased yield by 5% after switching to food-grade YTZ beads—translating to $100,000 in annual savings, as less raw material was wasted.

When selecting grinding beads, focusing solely on upfront cost is a false economy. The “total cost of ownership” (TCO) includes energy use, replacement frequency, labor for changeouts, and waste from rejected batches. High-quality beads often have a lower TCO despite higher initial prices.

Replacement frequency: Low-cost glass beads may cost $0.10 per bead but need replacement every 50 hours. YTZ beads, at $1.00 per bead, can last 1,000 hours—reducing labor and material costs by 80% over time. For a plant running 24/7, this translates to $50,000 in annual savings.

Energy savings: Efficient beads reduce milling time, cutting electricity use. A pigment manufacturer using ZrCe beads instead of glass saw a 15% drop in energy consumption, saving $30,000 annually and reducing their carbon footprint.

Waste reduction: Beads that ensure consistent quality reduce the number of rejected batches. A cosmetic company using inconsistent ceramic beads had a 10% rejection rate; switching to uniform YTZ beads dropped rejections to 1%, saving $50,000 in wasted materials (e.g., oils, pigments) and rework.

Not all grinding beads are created equal. Each material offers unique advantages and tradeoffs, making them better suited for specific applications. Below, we break down the four most common types with expanded technical details on their manufacturing and performance:

YTZ beads are the gold standard for high-performance wet milling, thanks to their unmatched combination of hardness, wear resistance, and chemical inertness. They are made by stabilizing zirconia (ZrO₂) with 3–5% yttria (Y₂O₃), a process that creates a tough, dense material with a tetragonal crystal structure—resistant to cracking under impact.

Key characteristics:

Density: 6.0–6.2 g/cm³ (heavier than most beads, enabling high-energy impacts).

Hardness: 9 Mohs (second only to diamond, ensuring minimal wear).

Wear rate: <0.01% weight loss per 100 hours (ultra-low contamination risk).

Chemical resistance: Inert to acids, alkalis, organic solvents, and high temperatures (up to 1,000°C).

Size range: 0.1mm to 20mm (versatile for fine to coarse grinding).

Manufacturing process: YTZ beads are produced via isostatic pressing (applying uniform pressure to powder) followed by sintering at 1,600°C. This creates a dense, uniform structure with <3% porosity, critical for wear resistance. Each batch undergoes rigorous testing: hardness (via Vickers indentation), size tolerance (±0.05mm), and impact resistance (surviving 100 drops from 1m onto steel).

Ideal applications:

Pharmaceuticals: API grinding (requires <1ppm contamination), injectables, and topical creams.

Battery materials: Cathode/anode slurries (lithium-ion, solid-state batteries) where purity and fineness (1–5μm) are critical.

Fine pigments: High-end paints, inks, and cosmetics (e.g., mineral sunscreens) where color consistency and particle uniformity matter.

Why choose YTZ: When contamination, fineness, or long-term cost savings are priorities. They are the most expensive upfront but offer the lowest TCO for high-value products.

ZrCe beads are a cost-effective alternative to YTZ, stabilized with cerium oxide (CeO₂) instead of yttria. They sacrifice a small amount of wear resistance for a 30–40% lower price point, making them popular for mid-range applications.

Key characteristics:

Density: 5.6–5.8 g/cm³ (slightly less dense than YTZ but still high for energy transfer).

Hardness: 8.5 Mohs (excellent for most industrial materials).

Wear rate: 0.03–0.05% weight loss per 100 hours (low contamination, suitable for non-pharmaceutical use).

Chemical resistance: Inert to most chemicals; less stable than YTZ in strong acids at high temperatures.

Size range: 0.5mm to 20mm (better for coarse to medium grinding).

Manufacturing process: ZrCe beads use a similar pressing and sintering process to YTZ but with cerium oxide as the stabilizer. This results in a slightly lower density but better toughness at lower temperatures, making them ideal for continuous industrial mills.

Ideal applications:

Agrochemicals: Pesticide and fertilizer formulations (requires consistent particle size for efficacy).

Inks and coatings: Industrial paints, wood finishes, and packaging inks (balances cost and performance).

Minerals: Grinding ores (e.g., copper, zinc) for concentration, where contamination from wear is less critical.

Why choose ZrCe: When you need better performance than glass or zirconium silicate but don’t require YTZ’s ultra-purity. They strike a balance between cost and wear resistance.

Zirconium silicate beads are a workhorse for general-purpose grinding, offering moderate performance at an affordable price. They are made from zircon sand (natural zirconium silicate), making them more cost-effective than zirconia-based beads.

Key characteristics:

Density: 4.2–4.6 g/cm³ (lighter than zirconia, suitable for lower-energy applications).

Hardness: 6.5–7 Mohs (good for soft to moderately hard materials).

Wear rate: 0.1–0.3% weight loss per 100 hours (higher than zirconia but acceptable for non-critical products).

Chemical resistance: Resistant to mild acids and alkalis; may dissolve in strong hydrofluoric acid.

Size range: 1mm to 30mm (best for medium to coarse grinding).

Manufacturing process: Zirconium silicate beads are formed by melting zircon sand at 1,800°C and spheroidizing the molten droplets (cooling them into spheres). This process is less energy-intensive than zirconia production, lowering costs.

Ideal applications:

Paints and coatings: Architectural paints, primers, and industrial coatings (where cost is a key driver).

Mineral dispersions: Calcium carbonate, talc, and clay grinding for fillers in plastics or paper.

Inkjet inks: Lower-cost inks for packaging or signage (less demanding than high-end pigments).

Why choose zirconium silicate: For cost-sensitive, high-volume applications where moderate wear resistance and contamination levels are acceptable. They are 50–60% cheaper than ZrCe beads.

Selecting the right bead isn’t just about picking a material—it’s about matching bead properties to your product’s needs. Let’s expand on how key bead factors (size, density, hardness, etc.) directly affect your final product:

Bead size is the most critical factor for achieving target particle size. Smaller beads create more surface area for contact with particles, enabling finer grinding, while larger beads deliver more impact force for coarse reduction.

Small beads (0.1–1mm):

Best for: Nanoscale grinding (1–5μm particles), pharmaceuticals, battery materials.

Effect: High surface area → frequent collisions → finer, more uniform particles. For example, 0.3mm YTZ beads in a basket mill can reduce API particles from 50μm to 1μm in 2 hours.

Risk: Too small and they may overheat heat-sensitive products (e.g., proteins, polymers) due to friction. They also require finer screens (≤0.2mm), increasing clogging risk with high-viscosity slurries.

Medium beads (1–5mm):

Best for: General-purpose grinding (5–50μm particles), paints, inks, agrochemicals.

Effect: Balance of surface area and impact force → efficient grinding without overheating. A 3mm ZrCe bead in a horizontal mill can process 100L/h of paint slurry to 20μm with consistent color.

Large beads (5–20mm):

Best for: Coarse reduction (50–200μm particles), mineral processing, ore grinding.

Effect: High impact force → breaks down large agglomerates quickly. A 10mm zirconium silicate bead in a vertical mill can reduce ore chunks from 1cm to 100μm in 1 hour.

Density directly affects how much kinetic energy a bead carries during milling. Heavier beads hit harder, reducing milling time but increasing equipment wear.

High density (5–6g/cm³: YTZ, ZrCe):

Best for: Hard materials (quartz, ceramics, metals) and fine grinding.

Effect: Fast milling (30–50% shorter batch times) due to high impact energy. A 5mm YTZ bead mill processes lithium cathode material 2x faster than a glass bead mill.

Consideration: Require mills with robust agitators (e.g., tungsten carbide-tipped) and ceramic liners to handle increased stress.

Medium density (4–5g/cm³: zirconium silicate):

Best for: Moderately hard materials (calcium carbonate, talc) and medium grinding.

Effect: Balanced speed and wear → suitable for continuous, high-volume processes like paint production.

Low density (2–3g/cm³: glass):

Best for: Soft materials (polymers, biological samples) and low-intensity grinding.

Effect: Slower milling but gentler on heat-sensitive products → reduces risk of degradation. A glass bead mill processing enzymes maintains 90% activity, vs. 70% in a zirconia bead mill.

Selecting the right grinding beads requires expertise in material science, milling dynamics, and your specific industry’s needs. At Sanxin New Materials, we offer expanded services to optimize your process:

Advanced Testing: Our lab uses laser diffraction (for particle size analysis) and inductively coupled plasma (ICP) spectroscopy (for contamination testing) to validate bead performance.

Custom Beads: We manufacture beads to unique specs, such as 0.05mm YTZ beads for nanomedicine or food-grade glass beads with <0.1ppm heavy metals.

Sustainability Audits: We calculate how longer-lasting beads reduce waste and carbon emissions, helping you meet ESG goals.

Grinding beads are the unsung heroes of wet milling, with a direct impact on efficiency, quality, and cost. By selecting the right beads—matched to your product, equipment, and goals—you can transform your process from a bottleneck to a competitive advantage.

Ready to optimize your milling chamber? Contact us to schedule a free process audit and discover how the right grinding beads can revolutionize your operation.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder