1. Significant cost and excellent performance

2. High wear resistance and longer service life

3. High crush strength and no break under high speed impact.

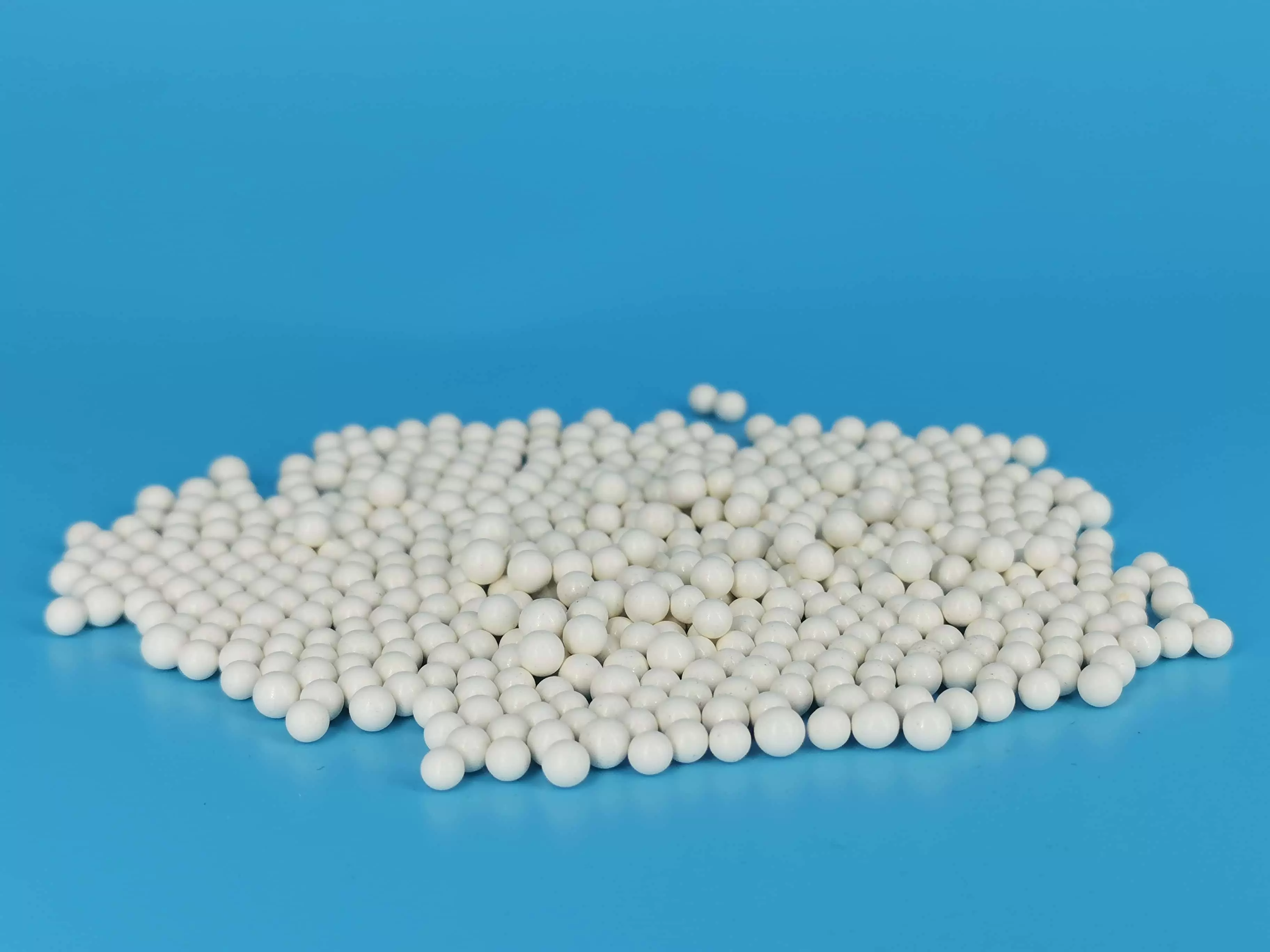

4. Smooth surface, good sphericity.

Zirconia Alumina Compound Grinding Media meaning Zirconia Toughened Alumina (ZTA) and Alumina Toughened Zirconia (ATZ), are two types of ceramic grinding media that offer superior wear resistance and high-performance capabilities.

ZTA grinding media is made from a combination of alumina and zirconia. The addition of zirconia during the manufacturing process improves the toughness and strength of the material, making it highly wear-resistant and ideal for use in grinding applications that require high-performance materials.

On the other hand, ATZ grinding media is made from a combination of zirconia and alumina. The addition of alumina during the manufacturing process improves the strength and toughness of the material, making it highly wear-resistant and suitable for use in demanding grinding applications.

Both ZTA and ATZ grinding media are widely used in the production of electronic materials, advanced ceramics, and mining and mineral processing. They offer excellent performance in both wet and dry grinding processes and are available in a range of sizes and shapes to suit different applications.

Sanxin presents SXAZ/SXZA toughened grinding media are made from high-quality and ultra-fine yttria zirconium powder and alumina powder. They possess high wear resistance and strength due to the high toughness of zirconia. The qualities and properties of these grinding media meet the international advanced standards.

Standard Size Range: ZTA is available in a standard size range spanning from 2.0 to 15 mm, providing versatility for various applications.

Exceptional Wear Resistance: Through rigorous comparison wear rate tests, ZTA has proven to be 4 to 30 times more wear-resistant than various high-quality High Alumina (90-92% Al2O3) grinding media available in the global market.

Density Parity: ZTA boasts a similar density to High Alumina media, making it an excellent substitute without compromising performance.

Superior Performance-Price Ratio: ZTA offers a remarkable performance-price ratio, delivering superior functionality while effectively reducing costs for users.

Type | Density (g/cm3) | Bulk density (g/cm3) | Major composition (%) | Crush strength (N) | V-Hardness (HV10) |

SXAZ | ≥5.2 | ≥3.1 | ZrO2: 75% Al2O3: 20% Other: 5% | ≥2000 (Ø2mm) | ≥1200 |

SXZA | ≥4.2 | ≥2.4 | Al2O3: 80% ZrO2: 15% Other: 5% | ≥1100 (Ø2mm) | ≥1100 |

0.03% Test Condition: a Lab Ball Mill (Jar Mill) Size: 7.6 L, Media Size: 40 mm, Media Feed: 4 kg (Media Filling Volume =23%), Water Feed: 4 L, Material Feed: 3 kg Zircon sand, Mill Speed: 90 rpm, Grinding Test Time: 24 hrs

B series:Φ0.4-5mm (Ultrafine grinding)

L series: Φ5mm, Φ6mm, Φ8mm, Φ10mm, Φ15mm (Coarse grinding)

Customization size available

Mining and Mineral Processing

Ideal for grinding and processing operations involving gold, silver, nickel, zinc, and lead.

Enhances efficiency in the comminution process, ensuring optimal results in mineral extraction.

Pigment and Ink Production

Perfect for pigment and ink manufacturing, offering consistent and reliable grinding performance.

Improves dispersion and particle size reduction, contributing to high-quality pigment and ink formulations.

Electronic Materials

Well-suited for electronic materials manufacturing, ensuring precision in grinding processes.

Enhances the production of electronic components by providing superior wear resistance.

Ceramic and Glass Production

Plays a crucial role in ceramic and glass production processes, offering durability and wear resistance.

Enables efficient grinding and milling in the production of ceramic and glass materials.

Food and Beverage Processing

Meets the demands of the food and beverage industry by providing reliable grinding performance.

Complies with stringent quality standards to ensure product safety and integrity.

Health Rating: 0 – None

Flammability Rating: 0 – None

Reactivity Rating: 0 – None

Contact Rating: 0 – Slight

Possible irritation through abrasive friction.

Risk of slipping if the product (beads) is spread out on the floor.

Although the product should not cause inhalation problems, its utilization can generate dust.

Eyes: May be abrasive through friction; treat as a particle in the eye.

This product is not combustible or explosive and is compatible with all standard firefighting methods.

Isolate the area and sweep the floor to collect beads, preventing slipping by rolling.

Wear eye protectors and a dust mask.

For operations generating dust, wear a dust mask and eye protectors.

Due to its weight, adhere to security rules when stocking; use safety shoes for handling.

Appearance and Odor: Odorless white beads

Solubility in Water: Insoluble

Volatiles by Volume at 21°C: 0%

Boiling Point: NAIF

Melting Point: Over 1600°C

Items unsuitable for recovery or recycling should be managed in an appropriate waste disposal facility.

Dispose of packaging and unused contents in accordance with governmental and local requirements.

Not regulated.

We will contact you as soon as possible!

Zirconia Alumina Compound Grinding Media

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder