Ultra-Wear

Superior Impact Resistance

High-Temperature Endurance

Anti-Off

Easy Maintenance

Versatile Application

The Bolt Weld Ceramic Liner Plate is a specialized solution designed for wear resistance in demanding industrial applications. This product features a ceramic liner plate that is securely affixed to a substrate through a bolt welding process.

1. Bolt Weld Ceramic Liner Plate Product Structure:

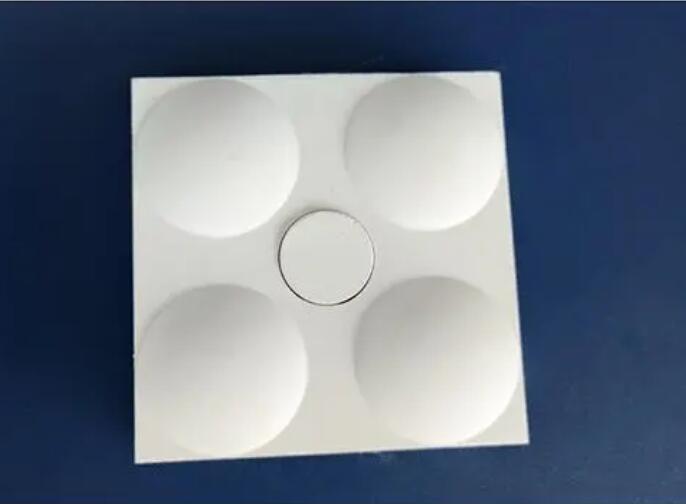

This high-temperature impact-type ceramic product is initially affixed to a steel substrate using welding bolts. Subsequently, the ceramic lid is screwed on, creating a robust wear-resistant ceramic liner. Specifically developed for equipment handling large particle materials with high drop, intense impact, and operating at high temperatures, it can withstand temperatures up to 500 degrees.

2. Bolt Weld Ceramic Liner Plate Features:

Ultra-Wear: Ceramic hardness exceeds 8, significantly extending equipment service life by at least 10 times.

Superior Impact Resistance: The ceramic product is designed with surface dimples, enhancing impact resistance by fivefold.

High-Temperature Endurance: Operates in temperatures ranging from 0 degrees to 500 degrees, meeting general material system resistance requirements.

Anti-Off: Each ceramic is welded onto the steel substrate using high-strength, high-temperature bolts, further secured with robust adhesive bonding, ensuring double fixation to prevent detachment.

Easy Maintenance: Facilitates convenient maintenance, allowing for efficient replacement or repair as needed.

Versatile Application: Suitable for a wide range of industrial settings where wear and abrasion are common issues, offering protection against the impact of abrasive materials.

3. Bolt Weld Ceramic Liner Plate Properties:

The Bolt Weld Ceramic Liner Plate possesses wear resistance, corrosion resistance, high-temperature resistance, impact resistance, and convenient construction.

The welded ceramic liner is initially affixed and then welded. The middle hole is welded to the steel plate using an iron bowl and finally filled with a porcelain cap. In comparison to bonded liners, the welded liner exhibits stronger impact resistance and can withstand higher temperatures, overcoming the limitations of adhesives affected by temperature.

4. Bolt Weld Ceramic Liner Plate Application:

4. Bolt Weld Ceramic Liner Plate Application:

Bolt Weld Ceramic Liner Plate serve as wear-resistant materials for coal conveying, material conveying systems, pulverizing systems, ash discharge, dust removal systems, and other mechanical equipment in thermal power, steel, smelting, machinery, coal, mining, chemical, cement, port, and wharf enterprises.

The Bolt Weld Ceramic Liner Plate is an effective solution for industries such as mining, cement, steel, and others, providing robust protection against wear and extending the operational life of equipment subjected to abrasive materials and harsh conditions.

We will contact you as soon as possible!

Bolt Weld Ceramic Liner

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder