Wear Resistance

Corrosion Resistance

High Temperature Resistance

Anti-Scouring

Smooth Inner and Outer Walls

Easy Installation

Reduced Maintenance

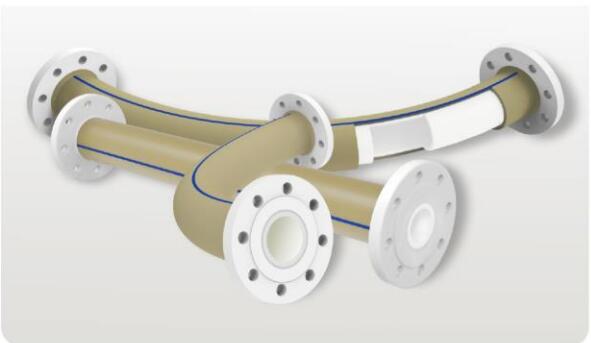

The integrally formed wear-resistant ceramic steel pipe is a specialized product designed for various industrial applications. Here's a breakdown of its product structure, features, technical specifications, and applications:

Steel Pipe:

Serves as the outer structural layer providing strength and support.

Designed to withstand the operating conditions of the specific application.

Wear-Resistant Ceramic Pipe Fittings:

Manufactured as a single, integral unit.

Composed of wear-resistant ceramics with superior durability.

Assembled through a firing process, ensuring a seamless integration.

Special Fillers:

Used in the assembly process to enhance bonding between the steel pipe and ceramic fittings.

Contribute to the overall strength and stability of the pipe.

Product Features:

Wear Resistance:

Exhibits exceptional wear resistance, outperforming ordinary pipes under similar conditions by tenfold.

Corrosion Resistance:

The seamless ceramic tube lining, combined with inorganic adhesive, resists corrosion from acids and alkalis.

High Temperature Resistance:

Capable of operating at temperatures up to 750°C for extended periods, suitable for a wide range of working conditions.

Anti-Scouring:

Resistant to erosion from larger particles without compromising structural integrity.

Smooth Inner and Outer Walls:

Facilitates unobstructed airflow, preventing material hang-ups and blockages.

Easy Installation:

Lightweight design (1/3 lighter than ordinary pipes) facilitates easy handling and installation.

Reduces the load on support and hanger equipment, saving material costs.

Reduced Maintenance:

Exceptional abrasion resistance minimizes the frequency of maintenance, resulting in cost and labor savings.

The integrally formed wear-resistant ceramic steel pipe finds application in various industries, including:

Tail Gas Treatment

Pulverized Coal Transportation

Fine Ore Transportation

Fly Ash Treatment

Limestone Transportation

Grain Transportation

Slag Transportation

Cinder Transportation

Cement Transportation

River Sand Transportation

These applications highlight the versatility and adaptability of the product in addressing different industrial needs related to wear and corrosion resistance.

We will contact you as soon as possible!

Integral Ceramic Pipe

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder